.

SETUP FOR USE WITH HYDRAULIC FLAT TAPPET CAMS UP TO 580 LIFT.

SEE OUR OTHER LISTINGS FOR THESE HEADS SETUP FOR USE WITH HYD. ROLLER AND SOLID ROLLER CAMS.

123cc COMBUSTION CHAMBERS 335cc runners.

This sale is for a set of heads (2 heads).

.jpg?width=1920&height=1080&fit=bounds)

GENUINE ARP ROCKER STUDS, AND COMP ADJUSTABLE GUIDE PLATES INCLUDED.

.jpg?width=590&height=370&fit=bounds)

ARP ROCKER STUDS INCLUDED. AND COMP ADJUSTABLE GUIDE PLATES.

.jpg?width=1920&height=1080&fit=bounds)

GENUINE ARP 7/16 ROCKER STUDS. # 100-7101

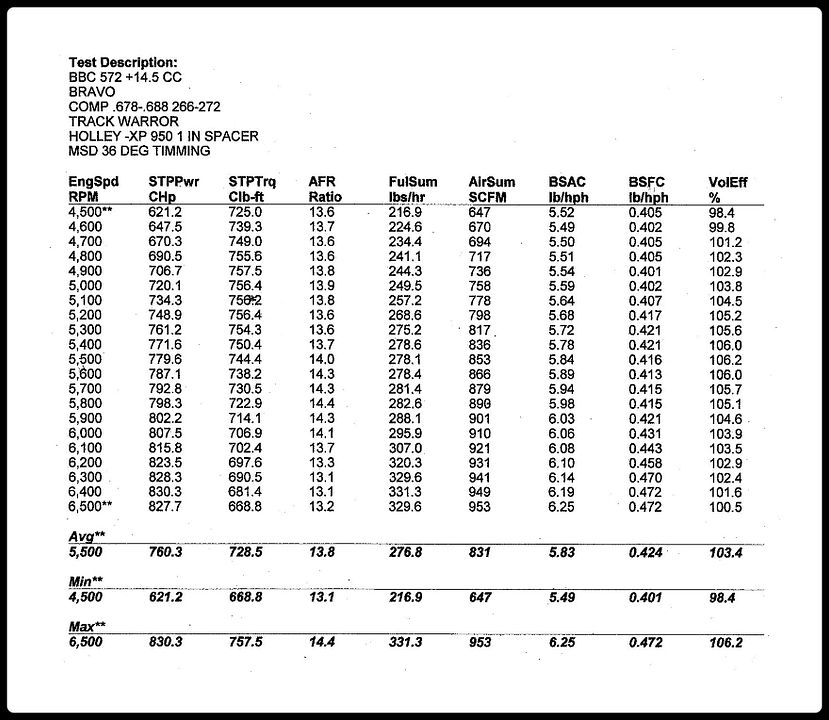

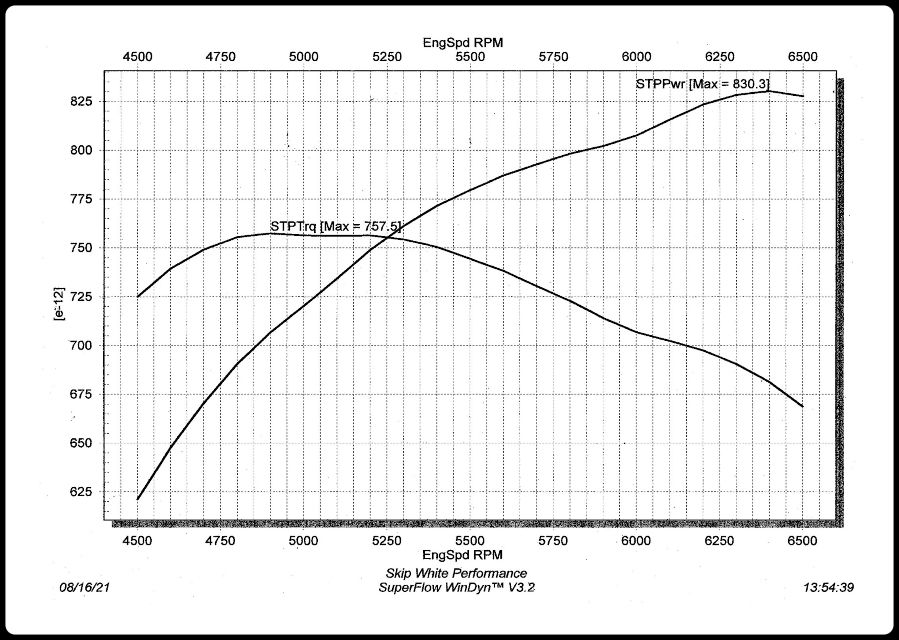

CHECK OUT OUR NEWEST DYNO RESULTS POSTED BELOW USING THESE HEADS ON OUR BBC 572 PRO-STREET ENGINE. 830hp ON PUMP GAS. IT’S AMAZING THAT THESE HEADS ARE CAPABLE OF MOVING THAT MUCH FUEL AND AIR TO PRODUCE THIS POWER IN A PUMP GAS STREET ROD ENGINE. THAT IS OUR BEST HP NUMBERS ON A PUMP GAS SETUP TO DATE, AND WHO KNOWS HOW MUCH MORE THEY ARE CAPABLE OF. WE HAVE ACHEIVED APPROX. 875 ON A RACE FUEL SETUP, (12 TO 1 COMP. RATIO) WITH DOMINATOR CARB. I WOULD SAY THAT’S GOTTA BE THEIR LIMIT, BUT WE DON’T REALLY KNOW. CONSIDERING THESE HEADS ONLY HAVE A RUNNER SIZE OF 335cc’s THEY HAVE BEEN THE BEST HEADS FOR THE MONEY WE HAVE EVER OFFERED. THE DYNO REPORT WILL BE THE VERY LAST ONE IN THE LIST OF DYNO REPORTS BELOW. WE WERE ALSO VERY HAPPY WITH THE WEIAND TRACK WARRIOR INTAKE USED ON THIS TEST.

Our eBay user id is: skipwhite, and our eBay store name is whiteperformance1. You may have noticed other sellers using a similar name offering similar products. These other sellers have capitalized on our name as we see it, and many customers searching for us will inadvertently find them, thinking we are one in the same company. There is only one “Skip White.” We are the original premier eBay seller under this name since approximately 2003. We have no other eBay names, nor are we associated with any other company regardless of the similarity in the name or location. Our official company name is Skip White Performance. Please see the article in the lower part of this ad for a more detailed explanation.

We also have these heads setup for use with hyd. and solid roller cams. See our other listings.

Important note.

These heads are not suitable on 396 or 402 engines that have the less then 4.250″ bore size. With the larger 2.250″ intake valve on these AFR heads, it can interfere with the cylinder wall. These heads are well suited on 4.280″ and larger bore BBC engines. The recommended compression would be from 9.8:1 to 10.5:1 with pump gas, taking advantage of the aluminum castings.

.jpg?width=1920&height=1080&fit=bounds)

The AFR Enforcer 335 bbc rectangular port heads are perfect for 454, 496, 540 and 572 street/strip engines. These are what we now use on our 505, 555 and 572 bbc engines. They produced 762 hp with our Comp 575 lift hyd. roller cam and single plane intake manifold on a 572 pump gas build. We’re estimating approximately 650 hp in a 496 build with the same mid size cam. None of the low cost bbc heads on the market have this performance that we know of. Fully built with premium hardware, ready to install.

Our cylinder heads are made from AC4B alloy and tempered to T6 standards. Details about this alloy are in the lower section of this ad.

We certainly know where to draw the line with low end products, and we continue to eliminate parts that we once accepted but for various reasons no longer carry. Sometimes it’s not that a particular product has had a problem that leads to its elimination; something better just comes along. The AFR 335 cylinder heads are that “something better” coming along. Considering the price is only slightly higher than our former line of heads, this has to be the best value in a set of cylinder heads we have ever offered. The performance has been outstanding on every combination we have tried them on. In the rare event you have issues with these heads, the problem will be addressed. So far problems have been non-existent.

.jpg?width=1920&height=1080&fit=bounds)

AFR 335cc ENFORCER ALUMINUM HEADS.

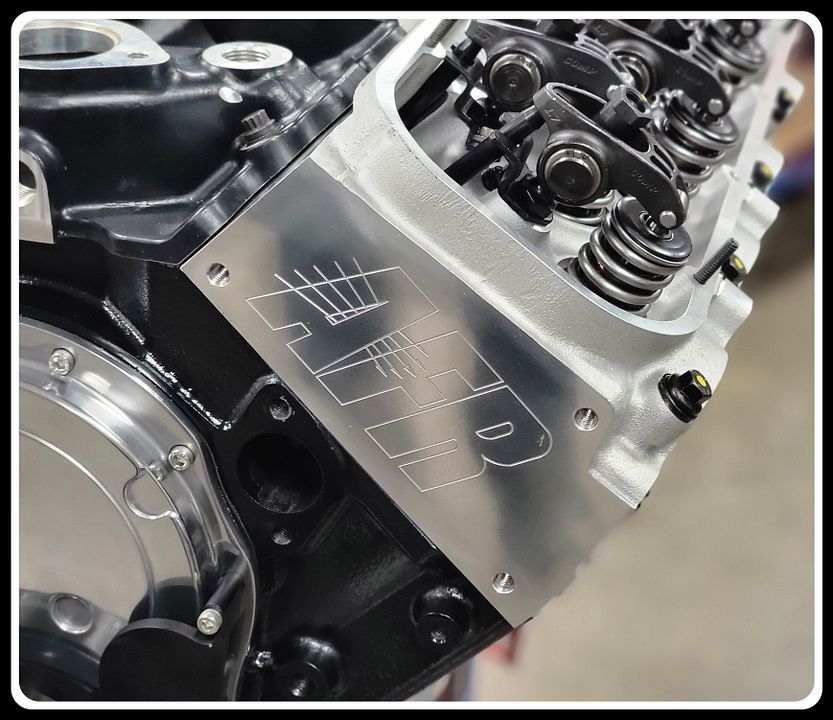

PICTURED BELOW IS A SET OUR AFR ENFORCER HEADS WE INSTALLED ON AN ENGINE IN THE BUILD PROCESS.

.jpg?width=1920&height=1080&fit=bounds)

The correct intake gaskets to use with these heads can vary greatly depending on what intake your using and whether your block has been decked excessively. Below are several common intakes we use in our engine room. There are other intakes on the market, but we have not used them, so we are unable to say exactly what they might use. As mentioned this can also vary on how much the block has been decked. If it has been decked a multiple times or to a great amount then it’s fair to say the thinner felpro 1275 gasket is the correct choice versus the 1275-5 thick version. If you are using the Edelbrock RPM Airgap, then it will always be the felpro 1274.

Profiler single plane, felpro 1275

Speedmaster/Procomp/Pro Products Hurricane single plane, felpro 1275-5

Edelbrock RPM Airgap dual plane, felpro 1274

Weiand Track Warrior single plane, felpro 1275

As for head gaskets, our experience has been that the felpro 1017’s are perfect for those using a 454 or Dart block for builds up to 505 cubic inch. For those using a later model 502 GM block these gaskets are NOT the correct ones to use. Were not sure exactly what the correct head gasket to use on the GM 502 blocks would be. When using a Dart Big M block or World/Merlin block to build engines 540 cubic inch or bigger the correct felpro head gaskets would be the # 1057 or 1067. One other important factor is that the head gaskets must have an opening of at least 4.560″ for the 496 cid builds. Were aware that these engines only have a bore diameter of 4.310″ but the AFR heads have a larger opening around the combustion chamber and require a head gasket with a large opening. This is standard with all aftermarket high performance aluminum heads. There are plenty of other brands of head gaskets on the market, and the felpro numbers mentioned can be crossed over to them.

In the lower section of this ad, you will find valuable information on how these heads perform when used with various engine sizes and cam combinations in street rod form. Please read the complete ad before purchasing.

Fully assembled with premium PBM competition grade valves, Melling springs, Comp retainers, Comp viton valve seals, Comp spring ID locators, Comp 10 degree locks. The hardware setup in these heads is for use with hydraulic flat tappet cams. Below is a detailed breakdown of the hardware used in these heads. We do offer these heads set up for all types of cams. See our other listings.

Notice the multi angle valve seat cut. These heads are designed to very high standards.

The AFR 335 heads pictured above are designed much like the high end heads on the market.

Pictured below are the AFR 335 heads in bare form to give you a view of them without the hardware from a different angle. The heads in this sale will be fully assembled.

We know of many sellers of aluminum high performance heads that claim to use good hardware. Chances are they don’t know the difference between low grade and high quality hardware. Failure to follow proper assembly procedures and the use of low grade hardware are what cause most problems. Good quality hardware and proper installation can determine how well the heads will function and hold up under hard use.

There is a vast amount of low grade hardware on the market at this time. Much of this no-name hardware is completely out of spec, and made from inferior materials. It will fail sooner or later, but prior to it failing, this garbage hardware will perform poorly. Many of the low priced heads on the market have such hardware in them. It’s not enough to ask them what brand hardware they use because it would be impossible for you to distinguish it from one brand or the other by simply looking at it.

The best we can do to prove what hardware were using in our heads is to post our invoices from the branded name companies that we purchase it from. Our invoices will show huge purchases of every bit of hardware used in these heads. High grade hardware is nearly double the cost, but we know for a fact that this is very important for the performance and longevity of a set of cylinder heads. Consider what happens should an engine drop a valve into the combustion chamber at any rpm. Complete destruction of a large portion of the engine is a great possibility. That’s a worst case scenario, but there are many other problems such as poor performance and damage to cam and lifters that can occur.

Valve size 2.250 and 1.88. These heads have the correct seat diameter to allow use of these valves.

These are true multi-purpose heads for street, drag race, and power boat applications. This set is an excellent upgrade over OEM cast iron heads on your big block engine. We honestly feel there is not a better set of heads for the price. These heads are tried and proven. The intake runner volume is 335cc, and the combustion chambers are 123cc.

You can reduce your engine weight by around 100 lbs. with the use of aluminum heads. You can also increase your power up to 250hp over an OEM 454 engine, depending on choice of cam and intake manifold. Compression ratio must be approx. 10.5:1 or higher on 454 engines. 496 or larger engines can get by with less compression but no lower than 10:1. Do not even attempt to use these heads on 427, 454, 496 engines with flat top pistons unless your running a blower or twin turbo setup, as they will not have near enough compression ratio to operate correctly.

We do our own assembly on our heads. See details below about our hardware and assembly procedure.

We also offer variations of these heads for use with all types of cams. Be sure of what type cam you plan to run before purchasing. Read the ad completely before purchasing.

The horsepower gain from the weight reduction of aluminum heads alone is noticeable, not to mention the fact that aluminum heads will allow you to run a bit more compression without the risk of detonation. The benefits are many to running aluminum heads. The most expensive cars in the world all run them. There are no drawbacks!

Tech support is available. We are confident that we offer the best advice in the business.

We also offer these heads in bare form, as many customers have selected a machine shop of their choice, as well as their own hardware. We hope you will check out our other listings for the many other items we have available.

The AFR cylinder heads are made from AC4B alloy and tempered to T6 standards. You may have heard the alloys 355 and 356 being used on many heads. The alloy used on our heads is similar but slightly different. The AC4B alloy is commonly used by automakers in Europe and Japan. Take notice of the Rm value. This value indicates the tensile strength of an alloy. As you can see, it’s higher than all the other common alloys in this chart. It’s no surprise as to why we have never experienced a failure of any kind with these heads. Zero failures in the casting, zero failures in the seats and guides. We have sold over 5000 pair of these heads over the past four years.

|

List of Standard Alloy Characteristics

|

Alloy +B4: H16

|

AC4B

|

AC4C

|

AC4CH

|

AC4D

|

AC7A

|

|

Mechanical

properties

|

Rm

(MPa)

|

345

|

285

|

260

|

320

|

245

|

|

R0.2

(MPa)

|

250

|

225

|

157

|

240

|

105

|

|

A

(%)

|

1.6

|

7.3

|

16.8

|

4.1

|

5.3

|

|

Temper

|

T6

|

T6

|

T6

|

T6

|

F

|

|

Features

|

High strength, small elongation

Castability: good,

for general purposes

|

Castability: good

Pressure resistance, corrosion resistance: good

|

Castability: good

Mechanical properties: good

|

Castability: good

Pressure resistance: good

|

Corrosion resistance: excellent,

anode oxidized

Castability:

not good

|

|

Examples of

applied parts

|

Crank cases,

cylinder heads,

and manifolds

|

Hydraulic parts,

transmission cases,

aircraft parts,

lighting components, etc.

|

Wheels,

engine parts,

hydraulic parts,

aircraft parts, etc.

|

Cylinder heads,

crank cases,

fuel pump bodies, etc.

|

Parts for overhead contact lines,

parts for ships,

business machines,

and lighting components for aircraft

|

|

|

|

|

|

Below are the actual flow numbers for the 335cc AFR heads. These numbers are true and accurate. The testing methods we use are considered to be on the conservative side. Some choose to show flow numbers for their heads that have been done in a way that shows numbers that are misleading in our opinion. Rather than base a set of heads on flow numbers, you would be much better looking at the horse power numbers they make, providing the dyno numbers are true. We now use the AFR heads on most all of our bbc engines builds all the way up to the 572 engine. The horse power numbers they produce are exceptional as compared to any of the low to mid range priced heads on the market. We have yet to have one customer complain about these heads not making the power they expected or the build quality, and hardware used. The runner size of these heads has been verified by us. They are correct as stated, 335cc.

|

Intake Flow

|

Exhaust Flow

|

|

.100

.200

.300

.400

.500

.600

.700

|

73

145

215

285

320

345

360

|

.100

.200

.300

.400

.500

.600

.700

|

71

120

165

200

228

249

266

|

Here is a rundown on the hardware used in the AFR 335 heads and the assembly process.

PBM/Erson Competition Series Valves.

The retail cost at most High Performance stores on the PBM Competition valves is $239

Notice in the picture below the concaved face of the valves. You will only see this on high end valves. Most other valves are either flat faced or have a dimple in the center.

The pictures below show our PBM valves installed in set of CNC’d combustion chamber heads. This is not actual combustion chamber of the PC heads. The pictures are to show you the valve face design.

Pictured below on the left is the PBM competition valve, and the other pic. is of our conventional style valve. It was difficult to show the back-cut feature in the picture, but note that the valve on the left has a third radius cut.

We are now using the Competition Series PBM valves in all of our engines. These are considered a high end valve. These valves have an undercut and backcut feature.

The backcut feature reduces valve weight by an average of 12.5 grams per valve. This weight reduction of approx. 220 grams off the complete set of valves has a monumental effect on acceleration, deceleration, and valve train life. It may be difficult to understand how this works, but rest assured, this is a huge reduction. The valve spring compression and rebound action will remain stable for a much longer time running lighter weight valves, as well as reducing valve float.

The backcut feature is not be mistaken for undercut. These valves have both features. Backcutting is an additional radius, but located on the head of the valve to increase the flow numbers and reduce valve weight. The flow increase is approx. 3-6 points on the flow bench, and possibly more, depending on the initial flow rate of the heads.

According to one of our machinists who built Winston Cup engines for 15 years, the exhaust valves had an additional radius cut on the outermost edge that allowed a better escape of the exhaust gas. This cut on the exhaust valve is in addition to the back-cut feature. The competition series are made from a much higher temp alloy than most other stainless valves. There are at least three levels of stainless valves on the market, excluding those used in very high level racing such as pro-mod. The PBM competition series is compared to the highest level of those three. As a final note, backcutting a set of valves is said to improve flow in the low lift area, and this is most desirable on street rods.

Below is a copy of one or more of our invoices from Engine Parts Warehouse showing a recent large order for our PBM valves. We have removed the price and our account number for privacy reasons. This is the best way we can prove to our customers that the valves we use in our cylinder heads are genuine PBM products.

Melling High Performance Dual Springs.

Our Melling springs are 1.46 diameter, with an inner spring and internal damper. Melling springs are made in the United Kingdom by a factory that is fully owned and ran by Melling. All of our engines using the AFR bbc heads use these springs. Spring failures are near non-existent.

AFR ENFORCER 335 FULLY ASSEMBLED BBC HEADS.

AFR ENFORCER 335 FULLY ASSEMBLED BBC HEADS.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=590&height=370&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

Reviews

There are no reviews yet.