Description

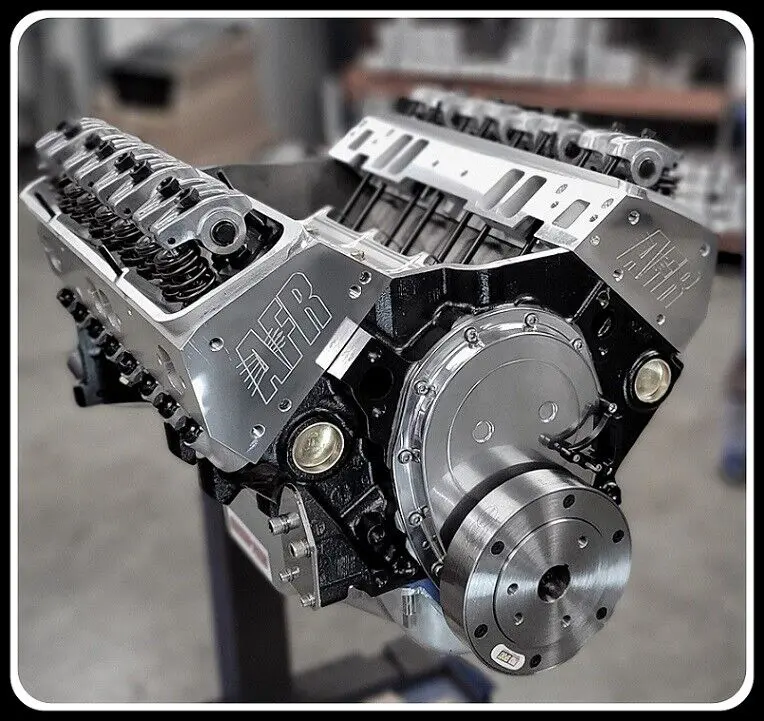

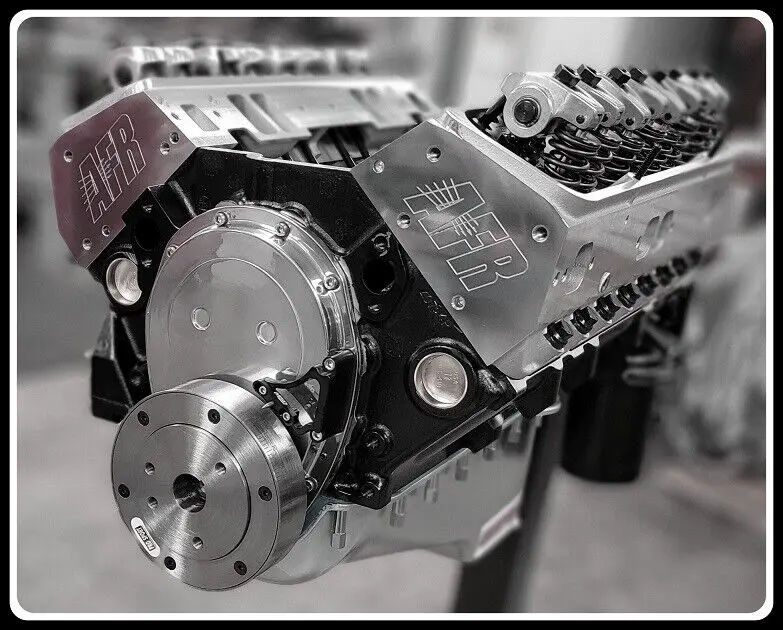

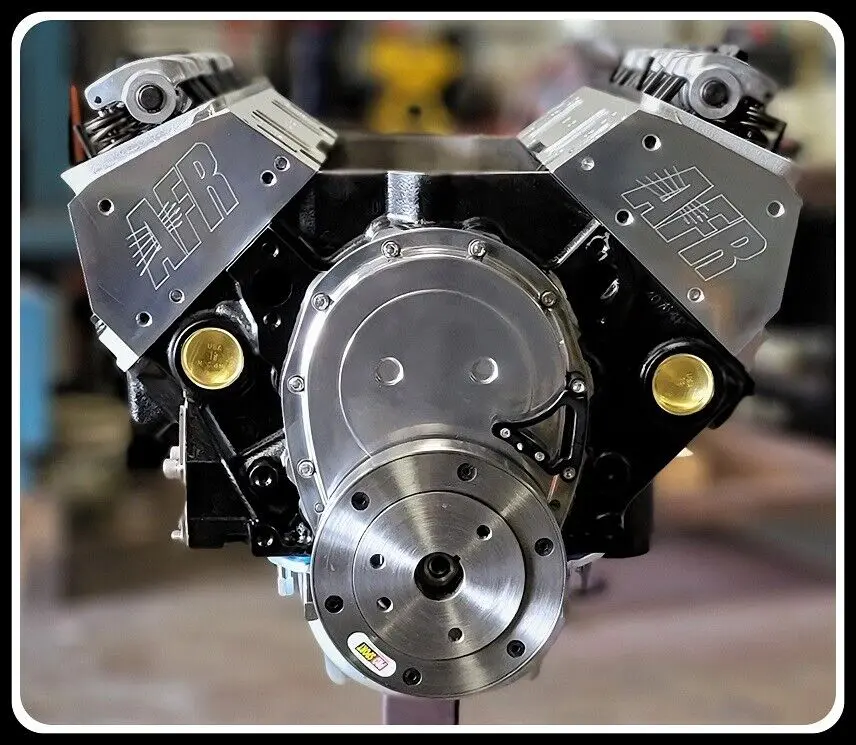

AFR Enforcer 200cc/65cc ULTRA HIGH FLOW CYLINDER HEADS

STRAIGHT PLUG, WITH STEAM HOLES, FOR SBC CHEVY 400, 406 ENGINES.

Setup for hydraulic roller cams.

200cc, (Actual size) RUNNERS, 65cc COMBUSTION CHAMBERS.

ARP studs, 3/8’s or 7/16’s, (your choice) and AFR 2pc. adjustable guide plates included.

|

I’m sure many of you have noticed there were 2 high performance engine builders in Kingsport, TN with similar names, leading to a great amount of confusion.

We are Skip White Performance, NOT White Performance and Machine or Marine

Due to the name similarity many customers looking for us online inadvertently find them, thinking we are the same company. Definitely not…there is no connection between the two companies. We don’t have a problem with free enterprise (competition). However, when the competition builds their foundation on such things as a name similarity and their supposedly long history of being in business, then we think it’s about time we set the record straight.

We have owned the original White Performance company since 2003, with the exception of the machine shop, which was owned by Fred White at the time. He continued to operate the machine shop and build engines for us while we continued selling online under the eBay user ID of skipwhite and the eBay store name of whiteperformance1. Our official company is Skip White Performance.

Due to their limited production capability and many disagreements about the engine building process and workmanship, we opted to open a full scale machine shop back around 2005. Fred White began competing against us even though our contract had a non-compete clause in it. Around this time we changed our company name to, Skip White Performance to make clear distinction between the two of us.

As our business grew, we expanded our machine shop, and putting heart and soul in this company, we have become the number one street rod engine builder in the nation. Our engine program is unlike any of the others out there.

Fred sold his shop, (White Performance & Machine) to an investor in 2016 and the new owners continue to reap the benefits from this confusion between the two shops. This investor lacked any knowledge of this industry. They continued to use the White Performance & Machine name. Contrary to what is posted on their website, Fred White is no longer associated with the company in any way. Their main spiel in advertising is, “In business since 1979,” when in fact, we purchased the White Performance company in 2003, with the exception of the machine shop.

The great pretenders continued capitalizing on our success due to the name similarity, but degraged our reputation. We were at one time getting calls nearly on a daily basis from people that did not realize there were two shops in this town with very similar names. Due to the confusion, there was an increasing amount of negative feedback that affected our name within the street rod community, when in fact we have a near perfect reputation in this industry. We have an “A+” rating with the Better Business Bureau and we have maintained the A+ rating for many years. As of this notice, (10/20/2021) the great pretenders have an “F” rating on bbb with a fraud alert. Their google reviews will also back up what were saying. Their ebay store was shut down and their score showed a huge amount of negative scoring. Please help us spread this information to any all of your friends in the hot rod community. They are now shut down. Hopefully we can some day restore our name that has been damaged due to the confusion between the two places.

All in all, we have been in this business going on 20+ years. Skip White’s passion has been owning and building street rods for 50 years on a personal level. The knowledge he has gained over time has allowed him to venture into this business and succeed to a very high level.

Help protect others in the hot rod community and share this info with them.

FAST FORWARD TO PRESENT DAY…We have become the largest street rod engine builder in the nation. Our engines, rotating assemblies, and cylinder heads are built to very high standards and shipped to our customers in a timely manner. We are a premier seller on eBay with a 99.5 or greater positive feedback score of well over 212,000 and growing.

Our engines are custom-built to our customers’ specifications and are shipped in approx. 2-6 weeks, perhaps sooner, depending on the season. Our rotating assemblies and cylinder heads usually ship out in about one week or less.

Now you know the real story, and we hope this helps with the confusion.

|

These heads used on a 350 engine build will

produce approx. 350-440 hp. on pump gas depending on cam, intake, rocker

ratio, and carb. When combined with a 383 stroker engine, the horsepower and

torque numbers increase dramatically. We have achieved 550 hp in our Stage 2.2

383 Super Stroker engine, setup for street use with the AFR/NKB heads, and able to run premium pump

gas.

We have thoroughly tested these heads on our Superflo 902s Dyno. The results have been amazing with

each and every cam combo possible.

Most sellers do no testing

whatsoever on the cylinder heads they sell. We do more than just flow testing

before we market a new style cylinder head.

They performed

faultlessly. Cam, carb, and ignition tuning led to so much testing, and we also

took the opportunity to make sure the new heads would not have any

reliability issues whatsoever. Our head builder noted the

excellent style of cutting on the seats in these heads. He also told

us that our line of intake manifolds mounted very well on the heads, and

the heads mounted perfectly onto the block. One of the worst

mistakes you can make in building an engine is to mismatch parts. We know about

combinations and how they work. Take a test drive in a car with over 500 hp vs.

a 300 hp or less and you will then see what you’re missing. The exhaust sound

under load is very pleasing. These heads will generate the power you need

without spending a fortune. We are very pleased with everything about these

heads. When price shopping, consider the quality of hardware.

Our Stage 2, 2.2, 3.0

engines are all now built using these heads. Read

the full story on how these heads performed on our 383 Super Stroker pump gas

engine. See our Stage 2.0 engine listing and the Stage 3.0.

-

We are not responsible for collateral damage caused by the use of this product.

RETURN POLICY

Should a problem occur, please contact us. If a return is necessary, please contact us for an RGA number and return authorization. The RGA number must be included on the return label. If an item is returned without an RGA number, it will not be processed. A full description of what the problem is needs to be included with any returned product with your contact info, and proof of purchase. Even though you may have explained the problem to us, and been granted permission to return the product, we must have a written explanation and a contact number included with the product. It is also recommended that you include the name of the person from our company that you have been in contact with. You must send the item back to us in a trackable manner (USPS Priority Mail, FedEx, etc.) and keep the tracking info of the returned product. Please give ample time for returns to be processed. Following these guidelines will make the return process work as it should.

PAYMENT AND SHIPPING DETAILS.

We offer great discounts on shipping. You only pay the full shipping fee on the highest shipping cost of your items, and HALF PRICE shipping on all additional items. Few offer discounts on shipping such as this. Our checkout system will automatically calculate your shipping discount at the time of final payment, providing you consolidate your payment.

You may receive a verification and tracking number shortly after purchase, but this does not necessarily mean that your product has shipped. It would be fair to say that 98% of products will be going out the day the shipping label is issued. On occasion, the product may not ship out until the next day after the label has been issued. Most products purchased late in the day will not be shipped until the next day.

If you checkout and start over, the auto calculator will not recognize the multiple purchases, and there will be no shipping discount.

UPS is our primary shipper. We are unable to ship to APO/FPO addresses or PO Boxes. Help us ship your order promptly by including your physical address at checkout. Below is a map representing the estimated delivery time to get to you from our location.

Delivery times may vary, especially during peak periods.

UPS delivers Monday – Friday, except for national holidays. If a package leaves here on a Thursday, and you are in a 2 day delivery zone, your package will deliver to you on Monday. Expedited shipping is available upon request for an additional fee. Please contact us for rates. The estimated shipping time is usually as the map shows, but many factors can delay this.

Alaska is in a 3-day ship zone, Hawaii is in a 6-day ship zone, and Puerto Rico is in a 4-day ship zone. Additional fees will apply to shipments to these areas, as noted below.

The shipping quoted in this ad is only for the 48 continental United States United States

THESE PRODUCTS ARE ILLEGAL TO OPERATE ON ANY PUBLIC HIGHWAY. THIS MEANS ANY PUBLIC PAVED OR UNPAVED ROADWAY OR IN A PUBLIC PARK. THESE PRODUCTS ARE ONLY LEGAL IF USED ON A DEDICATED RACING VEHICLE. VIOLATION ARE SUBJECT TO A MAXIMUM PENALTY OF $37,500 PER VIOLATION PER VEHICLE, REVOCATION OF REGISTRATION BY DMV, LOSS OF USE ON PUBLIC RIGHT OF WAYS AND PROOF OF CORRECTION OF THE TAMPERING.

|

Additional information

| Brand | AFR |

|---|---|

| Items Included | 3/8 or 7/16 Studs (specify in notes) & Guide Plates |

| Manufacturer Part Number | AFR-65cc-1001-274-SH |

| Finish | ALUMINUM |

Only logged in customers who have purchased this product may leave a review.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

Reviews

There are no reviews yet.