7/16" Studs

$1,126.16

Available

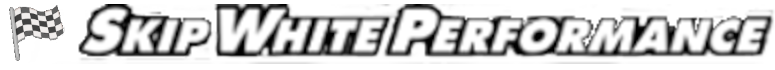

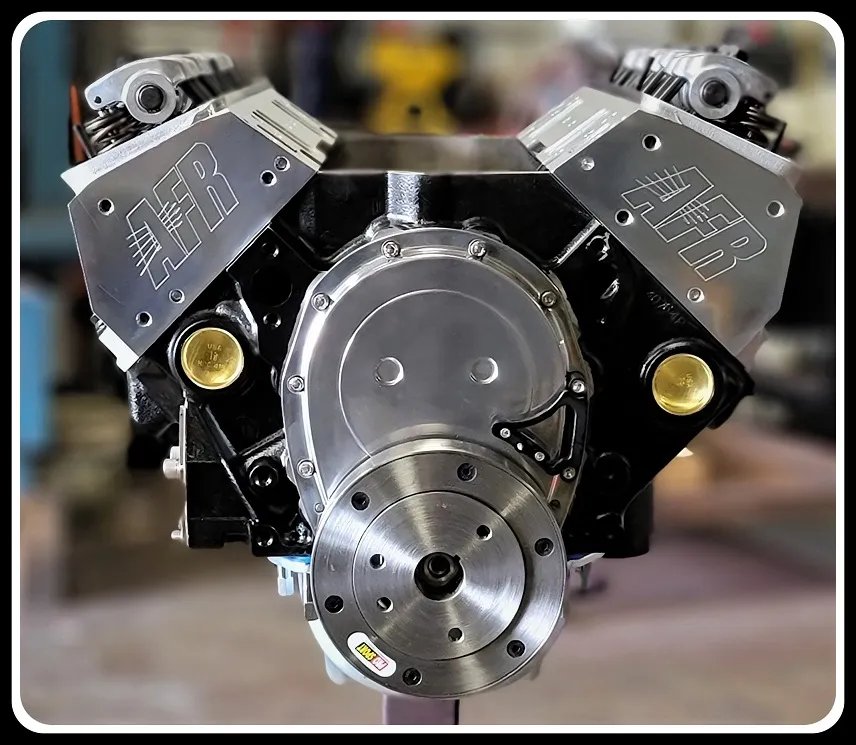

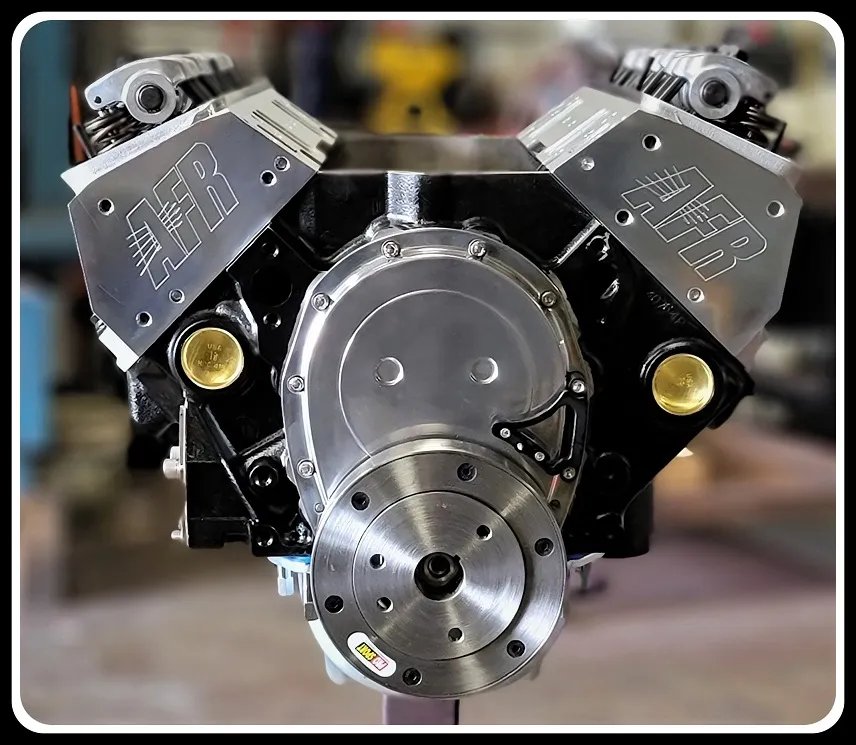

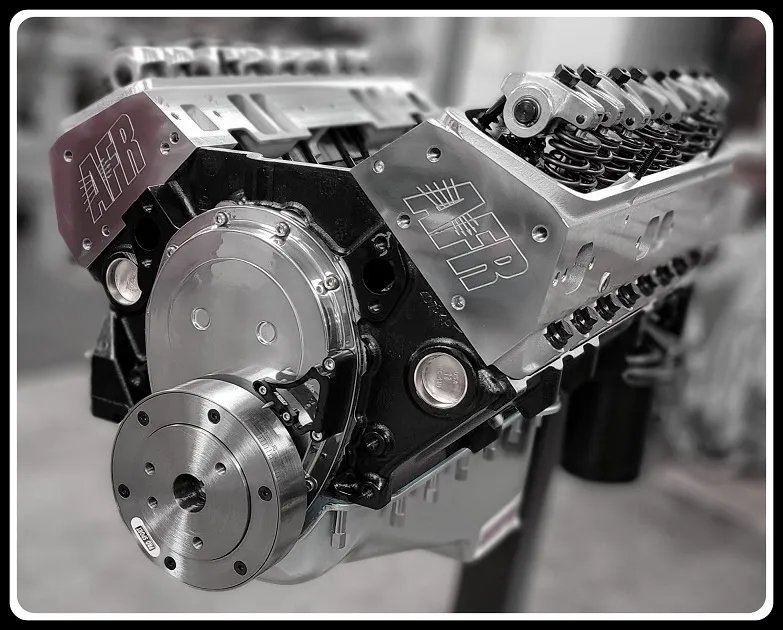

AFR Enforcer 200cc heads SBC 350 383 - 65cc Straight Plug [SP-272-AFR]

3/8" Studs [SP-272-AFR-3-8]AFR Enforcer Cylinder Heads

200cc/65cc Straight Plug

For SBC Chevy 327, 350 & 383 w/ hydraulic flat tappet cams up to .550" lift.

Not for use with roller cams.

After receiving many recommendations from our engine builders, we came up with the best quality, best flowing heads on the market relative to cost. The only way you're going to get a set of heads that flow as well or better will be to spend at least double the cost or more. We have installed these heads on all of our 383 and most of our 406 engines for the past 2.5 years. Many of these engines were dyno'd on our Superflo dyno . The engines had every possible combination of cam, intake and carb. The results have been amazing. These heads are excellent in design and quality. Our choice of hardware and precision assembly also contribute to the performance and reliability of the heads.

These heads can be used with outer perimeter or center bolt valve covers.

Fully assembled with the identical components found in our higher end CNC ported cylinder heads; such as ARP rockers studs, PAC Racing springs, Viton valve seals, AFR adjustable guide plates, machined bead valve locks (not stamped), hardened spring cups our one piece 8mm 21 4N Stainless Steel valves. They are available in straight or angle plug and bare without any parts for the DIY. Sold as a single piece, 2 are required per engine.

- ARP studs, 3/8's or 7/16's, (you pick)

- AFR 2pc. adjustable guide plates included

- Material: A356 Aluminum, see more details on alloy below.

- Intake Port Volume: 200cc true actual runner size.

- Intake Port Dimension: 2.080" H x 1.270" x 5/16 Radius

- Intake Port Location: Stock

- Exhaust Port Volume: 76cc

- Exhaust Port Dimension: 1.380" H x 1.420" W

- Exhaust Port Location: Stock

- Combustion Chamber Size: 65cc

- Valve Cover Bolt Pattern: Perimeter Bolt

- Valve Angle: 23°

- Valve Spring Pocket Diameter: 1.580" O.D

- Max Valve Spring Pocket Machining: 1.600" O.D

- Deck Thickness: .450"

- Minimum Bore Diameter: 4.000"

- Flat Mill: .006" per cc 56cc Maximum

- Spark Plug Dimensions: 14mm x .750" w/Gasket Seat

See our many listings for the AFR Enforcer heads for use with hyd. flat tappet cams, solid roller cams, with angle or straight plug design, and non steam hole applications.

Rocker Studs

These heads will include a full set of genuine ARP rocker studs. Choose the stud size, 3/8's or 7/16's. Adjustable AFR guide plates are also included.

Intake Gasket

The 1206 is the intake gasket part number, and that is mandatory for use with the Enforcer heads. Some intake manifolds will sit too low due to their design, and the 1266 extra thick intake gaskets may be required.

Head Bolt Washers

The AFR/NKB-27X heads require the use of special head bolt washers, and extended reach head bolts. Using stock length head bolts will not allow the use of the special washers required, as the OE bolts have a limited amount of thread on them. Not using the special head bolts and washers may cause serious damage to the cylinder heads.

Pushrods

We recommend not using stock GM pushrods with these heads. The spring pressures on aftermarket heads are somewhat higher than on OE heads. Combine this with the larger lift and duration cams often used, and stock pushrods may flex or permanently bend. The stock pushrods are usually made from a mild 1810 steel that has been heat treated. Under high rpm they will usually flex and cause a loss of lift resulting in a power loss. The engine will usually run erratically when pushrods are flexing. The Spintron valve train dyno proves that inadequate pushrods will flex to a great degree as engine rpm increases.

Some GM pushrods have a welded ball on them, and they stand a greater chance of breaking off with the use of larger than stock cams, and increased spring pressure.

We offer pushrods made from 4310 chromoly with an .080 wall thickness. They are superior to any stock pushrod.

The size that you will most likely need with the AFR/NKB heads will be 7.900". This size has worked well for us when using the Comp high energy or Scorpion brand rockers. There are many low cost pushrods on the market in the $29-$39 range. These low cost pushrods are totally unsuitable for use with these heads for the many reasons mentioned above, and they are not guide plate compatible.

They usually have a wall thickness of only .065"! These pushrods will cause problems when used on a high performance setup. There are many factors that can determine pushrod length requirements. The 7.900" length is the most applicable for those using a hyd. flat tappet cam.

Should you purchase a set of pushrods from us and find that the length is not suitable, you may return them, and we will send out the size you request. It is strongly recommended that you use a pushrod checking device to determine the exact size pushrod needed.

Stud Girdle recommendation.

If you are running full roller rockers, we recommend tall valve covers, and this can cause the oil that is pumped up into the top of the heads to not be deflected back down onto the valve springs, valve tips and roller rockers. The lack of oil on these parts can lead to not only a lack of lubrication but also to a lack of cooling on these parts. Heat transfers up the valve stem from the combustion chamber. This heat is very high in temp, and may cause serious damage to the valve guides, springs and roller rockers.

The cure for this would be to install a low cost set of stud girdles. Stud girdles increase stability to the rockers' studs, eliminating flex that is may be present to some degree when running cams several sizes over stock, not to mention increased spring pressures over stock. Stud flex robs your engine of power and smooth operation in the upper rpm ranges. As mentioned above, another very important aspect of using stud girdles is that they deflect oil directly back onto the valve springs, valve tips and roller rockers. On a stock engine this is not an issue due to the fact that stock valve covers are very close to the top of the rocker arms.

Edelbrock Performer EPS Intakes

If you are using an Edelbrock Performer EPS intake then you will need to use a 1205 intake gasket instead of the 1206. This is due to intake flange not covering the top of the 1206 intake gasket properly.

The 1205 is slightly small for the AFR Enforcer heads, and may need a very slight amount of trimming to avoid any gasket materiel hanging over into the intake runner. We have been through this procedure in our engine room many times for engines using the Performer EPS intake.

Part Number Breakdown

We offer 3 major types of SBC AFR heads, 272, 274 and 919.

272 designates the use of standard length valves, and single springs with a damper setup for hydraulic flat tappet cams.

274 designates the use of longer valves with dual springs with a damper, setup for hydraulic roller cams.

919 is a solid roller cam setup.

The heads come in angle or straight plug. Some blocks require steam holes. Be absolutely certain of what you need before buying.

Contact us if you need assistance deciding what you need for your build.

Recommended accessories

|

Part |

Part Number |

|

Intake gasket |

Felpro # 1206 Extra thick: Felpro # 1266 (some intakes): Felpro #1205 |

|

Head gasket |

Felpro 1003 for all 327,350 & 383 builds. |

|

Exhaust gasket |

5206 oval port. This can vary depending on header style. |

|

Valve cover gasket |

7483 extra thick 7484- regular thickness |

|

Head bolts |

ARP-134-3601 Strongly recommended, pun intended. Cheap hardware ruins motors! |

|

Head studs |

PCE-279-1001 |

|

Spark plugs. See important note. |

Autolite 3923, head range 3 NGK 4554, heat range 8 |

|

Pushrods - Length needed varies! Measure Twice, Buy Once! |

HB-BULK-7.900-16 recommended for 272 hydraulic flat-tappet cams This may vary depending on many factors. |

Alloy Information

Our cylinder heads are made from AC4B alloy and tempered to T6 standards. You may have heard the alloys 355 and 356 being used on many heads. The alloy used on our heads is similar but slightly different. The AC4B alloy is commonly used by automakers in Europe and Japan. Take notice of the Rm value. This value indicates the tensile strength of an alloy. As you can see, it's higher than all the other common alloys in this chart. It's no surprise as to why we have never experienced a failure of any kind with these heads. Zero failures in the casting, zero failures in the seats and guides.

|

List of Standard Alloy Characteristics |

||||||

|

Alloy +B4: H16 |

AC4B |

AC4C |

AC4CH |

AC4D |

AC7A |

|

|

|

Rm

|

345 |

285 |

260 |

320 |

245 |

|

R0.2

|

250 |

225 |

157 |

240 |

105 |

|

|

A

|

1.6 |

7.3 |

16.8 |

4.1 |

5.3 |

|

|

Temper |

T6 |

T6 |

T6 |

T6 |

F |

|

|

Features |

High strength, small elongation

|

Castability: good

|

Castability: good

|

Castability: good

|

Corrosion resistance: excellent,

|

|

|

Examples of

|

Crank cases,

|

Hydraulic parts,

|

Wheels,

|

Cylinder heads,

|

Parts for overhead contact lines,

|

|

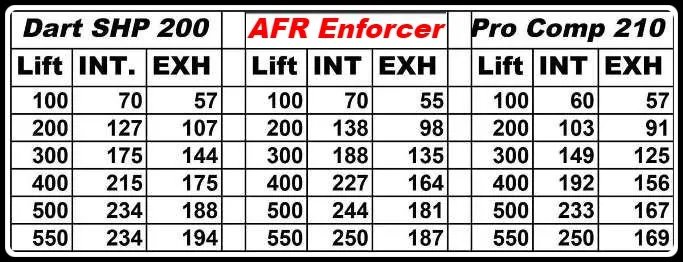

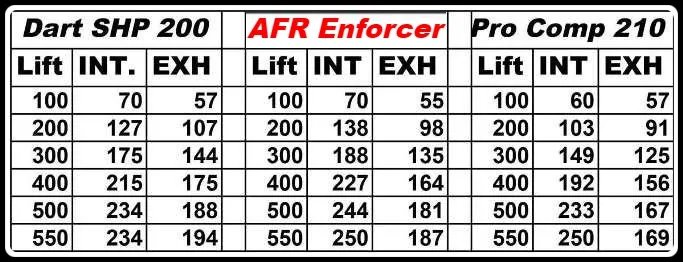

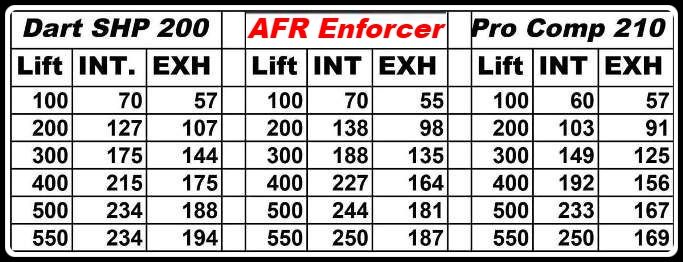

Flow Numbers

AFR-200s are superior to the Procomp heads in flow numbers, and also edge out the Dart SHP heads on the intake side. The intake numbers are far more important than the exhaust. The overall average flow numbers on the AFR/NKB-200 heads are higher than most any brand of non cnc'd cast aluminum heads on the market. We guarantee the flow numbers to be accurate, as well as the horsepower numbers produced by them.

Most importantly, all three of these heads were tested by the same person, on the same machine, (Superflo bench 1020) using the same testing method, on the same day. These numbers show the true difference between each brand, and that's what counts.

The difference in horsepower and torque generated by these new heads is monumental compared to the 210cc Procomp heads. We offer several different cam choices with our 383, 406 and 421 engines, and every combination has shown an increase of up to 50 horsepower and no less than 40 hp over the Procomp 210cc heads. We assumed the new heads would generate a considerable increase in power, but to our surprise, they generated more power than expected.

Many of the dyno passes were run to 6500 rpm as the large cam needed 6300-6400 rpm to make peak power, and you must run past this to determine the fall off point. The super sized cam (choice 1) was run on the heads towards the end.

Considering the size of this cam, it was very impressive to see zero issues with the heads or hardware. We made a good 25 passes with the big cam trying out different carb sizes, jetting, intake manifolds, timing setting, and adding the Super Sucker plate last.

The difference in horsepower and torque generated by the AFR Enforcer heads is monumental compared to any of the low cost SBC heads on the market.

Dyno Numbers

Below you will find 5 different cams paired with these heads. We've found a 350 engine build will produce approx. 350-440 hp. on pump gas depending on cam, intake, rocker ratio, and carb.

When combined with a 383 stroker engine, the horsepower and torque numbers increase dramatically.

We have achieved 550 hp in our Stage 2.2 383 Super Stroker engine, setup for street use with the AFR/NKB heads, and able to run premium pump gas.

Our team has thoroughly tested these heads on our Superflo 902s Dyno . The results have been amazing with each and every cam combo possible.

They performed faultlessly. Cam, carb, and ignition tuning led to so much testing, and we also took the opportunity to make sure the new heads would not have any reliability issues whatsoever. Our head builder noted the excellent style of cutting on the seats in these heads. He also told us that our line of intake manifolds mounted very well on the heads, and the heads mounted perfectly onto the block.

It's critical to match the engine components together for each application. We know the combinations and will work well. Take a test drive in a car with over 500 hp vs. a 300 hp or less and you will then see what you're missing. The exhaust sound under load is very pleasing. These heads will generate the power you need without spending a fortune.

Our Stage 2, 2.2, 3.0 engines are all now built using these heads. Read the full story on how these heads performed on our 383 Super Stroker pump gas engine. See our Stage 2.0 engine listing and the Stage 3.0.

Your results may vary

The results produced by these heads will vary greatly depending on the type of setup you are running. The engine combos we have dynoed are what most people use for cam and intake selection, and the results are listed below. The engines dynoed were many 383's, and several 406 and a few 421 cid engines in the 10:1 to 11.2:1 compression range. All ran on pump gas. This will give you an idea about the capabilities of these heads with combinations of cam, intake, rockers, and carb. This may also help you select the proper cam for your build.

As mentioned, below is just an excerpt from several of our engine adds using the AFR Enforcer heads. We also built and dynoed a 350 engine recently with the new AFR/NKB-200 heads for a customer, and will have the actual dyno results in this ad soon. The cams mentioned below are all hyd. roller cams. If you're using a lower lift than those listed below, then it would be fair to say the hp will drop, but not by much, providing your lift and duration are somewhat close to any of the cams mentioned below. This will give you an idea of what kind of power to expect with these heads, and it can certainly help you choose a cam and intake. These dyno reports show the heads to be the NKB heads. They are the exact same castings as the AFR Enforcer heads. The main difference between the two brands is the hardware used in AFR brand. This hardware used is of exceptional quality. The valves are 8mm metric size, and the valve springs are the Pacaloy high end series, same as used in their top of the line AFR Eliminator heads. The flow numbers picked up just a bit also over our NKB heads, and these high end valve train components also had a 810 gram weight reduction off the valve train. This has many benefits such as the reduction of valve float coming in sooner, and has a great effect on the ability of the lifters to stay operational at higher rpm.

Just to be clear, a cam is not included with the heads. This is just a guide to show what you may expect with a given combination when building an engine using the NKB heads.

Cam #1

Howards Cams

PART # 180345-10 This is a hyd. roller cam for use with OE roller blocks.

PART # 110345-10 This is a retro hyd. roller cam for use with non roller blocks.

Valve lift with 1.5 Rockers: Intake .565/Exhaust .580

Duration @.050": Intake .245/Exhaust .253

Lobe sep. angle: 110º

Recommended springs #: 274, See our other listings.

Below are our dyno results on one of our engines with a set of our AFR/NKB heads using this cam and a single plane intake. The horse power numbers will usually improve anywhere from 5-10 more than what the dyno results show after the rings have fully seated.

Official Dyno report on our 406 engine with this cam, flat top pistons, and a single plane intake.

Official Dyno report on our 383 engine with this cam and a single plane intake.

Cam #2

Howards Cams

PART # 180265-10 This is a hyd. roller cam for use in OE roller blocks.

PART # 110265-10 This is a retro hyd. roller cam for use in non-roller blocks.

Valve lift with 1.5 Rockers: Intake .530/Exhaust .545

Duration @.050": Intake .233/Exhaust .241

Lobe sep. angle: 110º

Recommended springs #: 274, See our other listings.

Official Dyno report on our 406 and 383 engines with the cam mentioned above. The 406 engine had a dual plane intake, yet still achieved over 500 hp with the NKB heads.

Cam choice #2 and a dual plane intake.

This cam and a single plane intake.

Cam #3

Howards Cams

PART # 180245-10 This is a roller cam for use in OE roller blocks.

PART # 110245-10 This is a retro style roller cam for use in non-roller blocks.

Valve lift with 1.5 Rockers: Intake .500/Exhaust .510

Duration @.050": Intake .225/Exhaust .231

Lobe sep. angle: 110º

Official Dyno report on our 383 engine with our AFR/NKB heads and a single plane intake. Considering the low lift and duration of this cam, the hp numbers are excellent.

Cam #4

AFR/NKB heads, a dual plane intake, a 770 cfm Brawler carb, and an MSD distributor.

This engine made 533 hp, and an amazing 549 lb. feet of torque at 4100 rpm. This engine had a dual plane intake on it. The single plane intake would have brought the hp numbers up to around 555.

Cam #5

236/242 duration

110 lobe separation

| Specification | Details |

|---|---|

| Intake Valve Dia | 2.02" |

| Intake Port Volume | 200cc |

| Intake Port Dimensions | 2.2" x 1.2" |

| Intake Port Location | Stock |

| Intake Gasket | Felpro# 1206 fits perfectly with most intakes. Should your intake drop too low, then the 1266 gasket will correct this problem. Our line of intakes have worked very well with the Felpro 1206 intake gaskets. |

| Head Gasket | Felpro# 1003 for 327, 350 & 383 builds. |

| Exhaust Valve Dia. | 1.600" |

| Exhaust Port Volume | 70cc |

| Exhaust Port Dimensions | 1.356" x 1.420" |

| Exhaust Port Location | Stock location & bolt pattern |

| Exhaust Gasket | Depends on what type exhaust you're using. Best to try and match up the gasket to your header or manifold. |

| Flow, Intake | See chart above. |

| Flow, Exhaust | See chart above. |

| Head Bolts | We strongly recommend ARP # 134-3601 head bolts. Must use extended reach with head bolt washers or head studs. |

| Head Studs | PC-2451-Studs (12pt) or ARP brand. |

| Manifold | Most any. Our line of intakes fit very well on the AFR/NKB heads. |

| Milling | Min. down to 58.5cc or 64.5 = .060". See info in this listing for details. |

| Pistons | Most 23° aftermarket pistons. |

| Push Rod Length | When running a hyd. flat tappet cam use 7.900 length. This may vary depending on many factors. |

| Push Rod Guide Plate | These heads include a full set of AFR adjustable guide plates. |

| Retainers/Locks | Chromoly Steel Retainers, with 7 degree AFR brand machined locks are used on all of our heads. |

| Spark Plug | .750" reach, gasket, Autolite 3923 or NGK 4554 for one step lower heat range than the Autolite. |

| Spring Pockets | 1.550" OD (.030" deeper max) |

| Springs | Pacaloy premium springs. |

| Valve Length | 5.015" (+.100") for hyd. flat tappet cams or + .200 for hyd. roller cams. |

| Valve Stem Dia | 8mm Metric |

| Valve Train | STD SBC 3/8" or 7/16" stud mount |

| Valve Guides | 1/2" OD Int = Mag-bronze, Exh = Phos-bronze (.002" press) |

| Valve Guide Length | 1.950" |

| Valve Guide Clearance | .0014" - .002" (with our .3415 dia. valve stem) |

| Valve Guide Spacing | 1.890" moved .030" from stock |

| Valve Seats | Hardened Ductile Iron, .006" press |

| Valve Seat Dimensions | Standard |

| Valve Seat Angles | Int = 32° - 45° - 60° - 70°, Exh = 37° - 45° - radius |

| Stud Girdle | Most all stud girdles will work on these heads with the exception of the AFR Eliminator stud girdles. |

| Torque | Head Bolts = 65 ft/lb, Rocker Studs = 50-55 ft/lb, Manifold = 30 ft/lb |

| Block Use | Any SBC Iron or Aluminum |

| Weight | 59-61 lbs fully assembled pair |

Attention Valued Customers!

When it comes to highly technical questions, our sales team at Skip White Performance might not always have the detailed answers you're looking for, especially on topics like installation procedures or tuning.

For those with detailed or specific questions, we strongly recommend checking out automotive forums and communities where these products are frequently discussed. These forums are a treasure trove of information and can provide the expert advice you need. Additionally, YouTube has countless tutorials and guides that walk you through the installation process and other technical details.

Please note: While we're here to provide top-notch products, we cannot be held responsible for any damage resulting from the use or installation of this product. Make sure to do your research and proceed with caution!

Thank you for choosing Skip White Performance!

Disclaimer

Skip White Performance is not liable for any collateral damage or incidental issues arising from the use or misuse of our products. High-performance parts are intended for experienced professionals and enthusiasts. Use at your own risk.Product Information

| UPC | SP-272-AFR-7-16 |

|---|---|

| Product Type | Shipped Product |

| Price (excl. tax) | $1,126.16 |

| Price (incl. tax) | $1,126.16 |

| Tax | $0.00 |

| Availability | Available |

| Shipping Cost | 0.0 |

| Brand | Air Flow Research (AFR) |

| Engine Block | BBC |

| Number of reviews | 0 |

Customer Reviews

This product does not have any reviews yet.