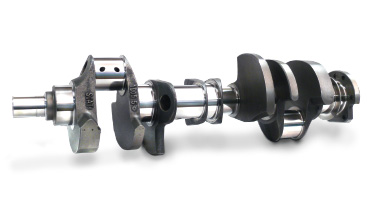

Best Cranks on the Market

SCAT CRANKSHAFTS are a a pioneer in the grass roots of racing heritage. Their PRO STOCK CAST, SERIES 9000 CAST, 4340 FORGED STANDARD WEIGHT & F-43 LIGHTWEIGHT Crankshafts are designed and engineered for the budget minded engine builder and racer alike.

They are designed for high strength and fatigue resistance. The Scat cranks are 25% stronger than stock OEM cast cranks and are the best value around. The Scat crankshafts are the best way to build a strong bottom end for your street rod, dirt track/circle track racing, and drag strip racing performance engine.

Our Scat crankshafts are brand new, factory sealed. Beware of other sellers offering no name cranks. We sell plenty of no name products but we have seen too many issues with the no name cranks on the market.

Manufacturing

“How Do I Identify A SCAT Crankshaft?”

SPOT THE QUALITY

For the last 50 years SCAT has been one of the foremost leaders in innovative crankshaft and connecting rod design. Here is some details on our product that will help you to avoid purchasing fraudulent components.

GENUINE SCAT CAST CRANKS

The SCAT name is cast in raised letters on the arm of the first counterweight. This helps identify a certified SCAT Crankshaft.

GENUINE SCAT BILLET AND FORGED CRANKS

Scat’s name is acid etched on the face of number 1 counterweight. Job number and or stroke is stamped adjacent to acid etching.

GENUINE SCAT SPORT COMPACT CRANKS

SCAT name is acid etched on face of counterweight and stroke stamped

SCAT FLEXPLATE PACKAGING

Part number stamped on product

GENUINE SCAT PACKAGING

Consists of 350 lb. test box. SCAT cranks are protected with special SCAT rust protective coating, wrapped in rust preventative paper and suspended in the box with SCAT designed 2 piece foam blocks within a box to insure you receive your crank in a ready to use.

Balancing

We do all balancing in house. Our machinist who does the balancing made special note of how much harder these cranks were compared to any of the other cast nodular cranks on the market.

Thrust Clearance

We recommend that you check the thrust clearance on the crank before assembling the engine. This is recommended on any crankshaft, regardless of brand or cost. Also check your main and rod journal size, as it's also not uncommon to find some cranks on the small or large side by as little as half a thousandths or less.

On occasion, our engine shop requires a half shell to correct this for perfect clearance. I would say this happens on about one out of 20 engines, but we really try to keep our tolerances in the middle zone. If you encounter this, we have 1 thousandths under bearings, and you should use them if needed, as this is important for engine longevity.

Don't confuse what we are saying with a turned crank. Those cranks are smaller by 10 thousandths or more. It's not uncommon for many GM stock cranks to have 1 under or over bearings in them right out of the factory. We rarely run into this, but don't assume anything. Just check before installing, and let us know if you need a set of 1 under or over bearings or the half shells.