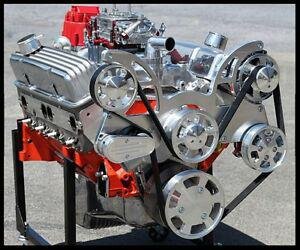

CHEVY TURN KEY 427 STAGE 5.2 DART BLOCK AFR HEADS CRATE MOTOR 628 hp-SERPENTINE MANLEY

$14,495.00

Available

Introducing our Turn Key Stage 5.2 Roller cam 427 cid 628 hp engine.

OUR 427 AT 4.125" BORE X 4.00" STROKE ENGINES ARE QRP RATED.

- DART SHP BLOCK WITH SPLAYED MAIN CAPS. COMMONLY USED IN ENGINES BUILT TO 800+ HORSE POWER.

- AFR FULL CNC'D ALUMINUM ALLOY HEADS 75cc COMB. CHAMBERS 2.08/1.60 VALVES.

- COMP HYD. ROLLER CAM AND PREMIUM BRAND TIE BAR STREET STRIP ROLLER LIFTERS.

- SA GEAR BILLET TIMING SET WITH TORRINGTON BEARING AND ROLON CHAIN 9 KEYWAY. TOP OF THE LINE.

- SCORPION RACE SERIES ROCKERS 1.5 OR 1.6 RATIO. THESE ARE SCORPION'S BEST ROCKERS.

- MANLEY 4340 FULLY FORGED STEEL NEUTRAL BAL. CRANKSHAFT. 800+ HP RATED, CLEVITE HP, (HIGH PERFORMANCE SERIES) BEARINGS. BALANCED ON OUR CWT BALANCER TO BELOW 2 GRAMS.

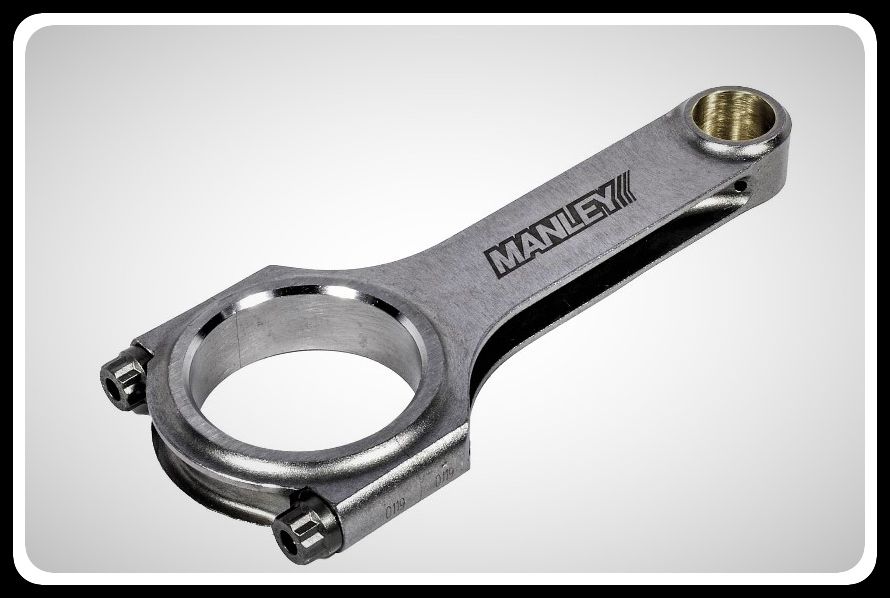

- MANLEY H-BEAM RODS 7/16 ARP CAP SCREWS. CIRCLE TRACK PROVEN. 700+HP RATED.

- WISECO PREMIUM FORGED PISTONS. 800+HP RATED.

- ATM INNOVATION DOUBLE PUMPER CARB WITH DUAL METERING BLOCKS.

- MELLING M-SELECT SERIES OIL PUMP WITH M-SELECT DRIVE ROD.

- CHAMP CUSTOM OIL PAN WITH OIL CONTROL SYSTEM.

- ALUMINUM WATER PUMP

- ATI SUPER DAMPER SFI RATED

- TWO YEAR WARRANTY .

This engine is designed for street/strip use. Premium pump gas friendly.

Two year warranty, see details below.

This engine is designed to have a high level of drivability, or street manners. Cams #3 and #4 are our favorites for offering exceptional low end and mid range performance plus max drivability without needing to deepen final gearing or the need for a high stall speed torque converter.

If you choose to go with the Hurricane single plane intake and the first choice cam with 1.6 rockers, it will bring the hp numbers up to approx. 628 . We do not recommend the single plane intake combined with cam choice 1 on any car that is over approx 3,200 lbs and/or cars with a steep (tall) final gear.

Please read the cam info provided below on the four cam choices before purchasing this engine. It is very important that you choose the correct cam and intake for your car and its intended purpose.

Here are a few good reasons why we think the 427/434 engine is a better choice than the 383 or 406 engine.

1. The 427/434 will accelerate most medium to heavy cars dramatically quicker than the common 383's on the market. The main difference between a 427/434 and the 383 is that the 427/434 torque comes in much lower. The difference is so dramatic that you would estimate the engine to have a much higher horsepower rating than it actually has. If you're not familiar with the 427/434 engine, do an internet search on SBC 427 vs 383, and you will be convinced of the difference. There is no inherent weakness in the 427/434 engine when using a Dart high performance block. These engines are built to last. All parts used have much higher hp ratings than this engine is producing. The stroke on this engine is at 4.0.

2. The exhaust note that this engine produces is much deeper than that of any of the smaller cubic inch engines on the market. The difference is dramatic to say the least. The stroke on a 427/434 is at 4.0 compared to 3.750 that is used in a 383 or 406.

3. This engine can be installed in medium to heavier cars without killing acceleration, having to deepen the final gear, and needing a huge stall converter. This engine will accelerate a 3600 lb or heavier car much better than the 350 or 383.

4. Very low maintenance, decent drivability, yet costing only slightly more than building a 383 or 406 street rod engine. Horsepower will vary, depending on cam, carb and intake choice. You have up to four different cams to choose from, and two styles of intake manifolds plus two rocker ratios.

5. Longevity, reliability and low maintenance. You don't have to turn the engine to a critical rpm range to produce its max hp output. There is nothing unsafe about running an engine that's as well built as this up to approx. 6,200 rpm. Our AFR fully cnc'd aluminum heads use very high quality hardware. The new Dart Super High Performance block would be indestructible if built to the power rating of this engine. The fully forged Manley Pro-Series crank and Manley H-Beam rods are rated well above this engine's output. The Wiseco Racing pistons are rated at 800+hp. The protection against detonation is at its highest with these type pistons.

6. Should you ever decide to sell your car, the resale value of a street rod with a 427/434 engine is very desirable compared to those running 350's or 383's. No 383 can be built up to the level of a 427 while running pump gas with the same compression. The power and torque numbers down low in the rpm band are what make the 427 such an incredible engine, compared to the 383.

We do a full test run on every engine we build on a test mule. The engine is run for two intervals of 15 minutes each, and every possible issue is addressed. When you install the engine, you must verify that the timing is set at the correct value, and the fuel to air ratio must be verified. We also include an engine stand like the one pictured, wheels included, and an engine lift plate.

As of 9/15/2013 we completed installation of our brand new Super Flow 902S dyno. In the past, we outsourced our dyno work. We were unable to do the research and development we truly wanted, and this prompted us to make the $105,000 investment. It’s been one of the best investments we have ever made. Every aspect of our engines can now be monitored, calibrated, and tuned. Best of all, we can now see what combos generate the best power, with consideration to drivability.

One thing we have noticed is that the de-tuned engines with different cam and intake combos certainly do have less top end horsepower than expected, but the torque increase in the low rpm range is much greater than in the higher horsepower setup. This increase in torque down low is what you want if you’re sporting around on the street, rather than all out racing. The de-tuned version of this engine will also allow you to set the car up closer to stock and increase drivability to a very high degree. Throttle response is also noticeably better.

The build sheet is as follows:

Block Specs.

Dart SHP block, splayed caps

The block is bored to size with our new Centroid touch probe machine. Few machine shops have a machine of this accuracy.

We also deck the blocks to an RA finish of approx. 15 or better. The decking procedure is also done by our Centroid CNC machine.

We often find many brand new blocks to have a sloping deck of up to 4 thous. When we're finished decking the block, it is within approx. .001 accuracy from end to end. Many machine shops fail to catch this as the machinery they use does not allow for such accuracy.

We then plate hone the block with our new Sunnen SV10 diamond hone machine. This is also a very advanced machine that hones the block with a finish unlike conventional machines.

The final step is to clean the block in our high pressure block washer.

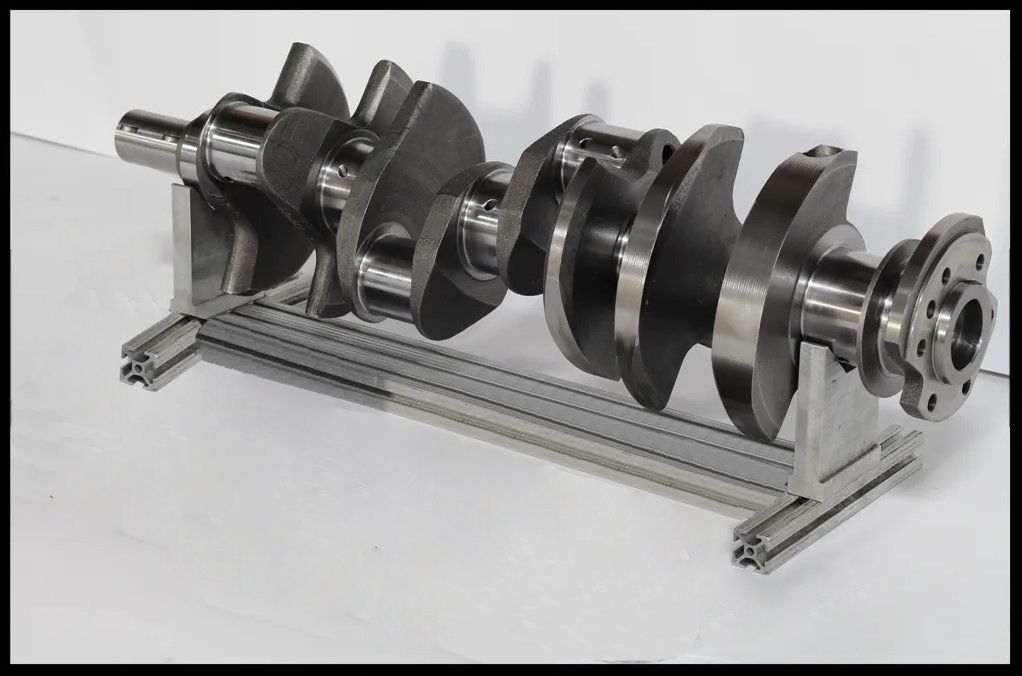

Pictured below is the rotating assembly that comes in this engine.

(file photo, actual parts may vary, see details below)

The photos above and below are file photos. Actual appearance may vary. This picture is to give you an idea of parts used in the rotating assembly portion of this engine. All parts are brand new, first line, unblemished, and balanced in house.

READ THIS LISTING COMPLETELY BEFORE YOU BUY ELSEWHERE!

Crankshaft Specs.

- Crankshaft: Manley Pro-Series

- Crankshaft Stroke: 4.00"

- Crankshaft Material : 4340 Fully Forged

- Journal Diameter: STD SBC

- Rear Main Seal: 2 pc RMS

- Rods: Genuine Manley

- Rod Type: Manley H-Beam, Bronze Bushed.

- Rod Length: 6.00"

- Rod Material: Forged 4340 Alloy.

- Rod Bolt/Cap Screw: ARP 2000 Cap Screws.

- Pistons: Wiseco Fully Forged. High Performance for street/strip use.

- Piston Size: 4.125"

- Dome Volume: RD D-cup Dish. Comp. ratio calculates out to approx. 10.5:1

- Compression Height: 1.015

- Piston Material: Forged 2618 Aircraft Alloy

- Piston Rings: Total Seal High Performance, Moly, Standard Tension.

- Ring Size and Fit: 1.5mm 1.5mm 3.0mm File Fit.

- Ring Material: Ductile Iron/Cast/Stainless/Moly

- Main Bearings: Clevite HP High Performance

- Rod Bearings: Clevite HP High Performance

- Balance: In House on CWT balancer.

- Damper: ATI Super Damper SFI Internally balanced.

- Flexplate: Heavy Duty SFI 168 tooth or 153 tooth. Manual Trans. flywheels available. Internally balanced.

Our Wiseco Forged pistons are custom designed with an increase in compression height. This has many advantages. Here are a few facts about compression height and deck height.

Our custom made pistons have a compression height that is .010 taller on bbc pistons, and .015 taller on sbc pistons, as compared to most all of the catalog pistons on the market. We find this to be a very valuable feature.

Since our pistons sit at a taller than normal compression height, we only have to remove approx. .005-.010 off the deck surface of the block. Our goal is set the piston at zero deck (flush with the deck surface). This maintains the deck's thickness, making it much stronger than a block that has been cut down .025. The engine will also run a bit cooler with a thicker deck. It's well known that the deck dissipates much of the built up heat an engine generates. This also allows for future deck re-surfacing without compromising the integrity of the block. On our bbc engines, we actually leave the piston about .003 to .005 in the hole to allow for possible piston rock. Our sbc engines will have the pistons setting right at zero with the deck.

These pistons are also suitable for use with mild nitrous or blower setups that do not exceed a 25% increase in horsepower over the engines naturally aspirated rating.

The picture above is a file photo of our Wiseco piston. Flash glare on the piston top seems to have enhanced the milling marks. These are hardly visible with the naked eye.

The New Manley Pro-Series #190130 with 6 counterweights, 4340 Forged Crankshaft.

The picture below is a generic file photo

The picture below is a file photo. Actual appearance will be different.

Some of the benefits of the new Manley Pro-Series crankshaft.

Manley Pro Series crankshafts are considered a top tier level crank as compared to the more common brands available. They feature forged 4340 construction and undergo a multi-step heat-treatment process and are then nitrided for added strength. The crankshafts are stress-relieved, shot-peened, and magnafluxed. Manley Pro Series crankshafts have micro-polished large .125 in. radius journals, gun-drilled mains, and lightened rod journals for weight reduction. The counterweights are fully profiled and they are designed for internal balancing. These crankshafts will include a spec. sheet that validates journal sizes and checks for taper on each journal as well as finish quality. As of this date, 4/15/24 We have now upgraded all of our 427 and 434 short block kits and engines with the Manley Pro Series crank.

Total Seal High Performance Rings.

Crank Polishing.

Our choice of rods are the Manley 6.00 H-beam rods with ARP 2000 cap screws.

The Manley H-beam rods are very high rated in the racing industry. They easily outrank most of the other common brands on the market.

-

Manley H-beam rods are finished to exacting tolerances to ensure precision and performance. Every aspect of the rod is treated with attention to detail, from the final hone size to the thread detail, bend, and twist. Our Manley H-beam rods all have high strength ARP 2000 bolts.

-

Manley H-beam rods are manufactured from 4340 alloy forgings and are fully machined, heat treated, stress relieved, shot peened, and magnafluxed.

-

-

Manley H-beam rods are much stronger than any regular I-beam rods because they have a thicker web, which provides stronger support in every way when compared to other low cost rods on the market.

We have noticed some engine builders using low cost generic rods and crankshafts in their engines. These non-branded, (no-name) products are often poor quality in many ways. You will notice many of the low end engine builders fail to mention the actual brand of the rods or cranks used in their engines. Upon further investigation you will find such parts not to be a branded name product. They may label these parts with a name, but one that is totally unrecognizable in the industry. Our experience in years past with such rods and cranks has been disappointing to say the least. Besides the obvious issues such as incorrect sizing and machining that is difficult to correct, the questionable alloy these items may be produced from and the potentially incorrect heat treating methods used, could prove to be disastrous. Little can be done to verify this and nothing can be done to correct it. Failures of such critical parts will usually result in catastrophic damage to the engine. As you may have noticed, this is why we name the brand of every part used in this assembly.

Genuine ARP 2000 cap screws.

We have noticed some engine builders using low cost generic rods and crankshafts in their engines. These non-branded, (no-name) products are often poor quality in many ways. You will notice many of the low end engine builders fail to mention the actual brand of the rods or cranks used in their engines. Upon further investigation you will find such parts not to be a branded name product. They may label these parts with a name, but one that is totally unrecognizable in the industry. Our experience in years past with such rods and cranks has been disappointing to say the least. Besides the obvious issues such as incorrect sizing and machining that is difficult to correct, the questionable alloy these items may be produced from and the potentially incorrect heat treating methods used, could prove to be disastrous. Little can be done to verify this and nothing can be done to correct it. Failures of such critical parts will usually result in catastrophic damage to the engine. As you may have noticed, this is why we specify the brand name and series of every part used in our engines.

ATI SUPER DAMPER SFI INCLUDED.

INTERNALLY BALANCED, SFI rated, 6.325" DIAMETER REDUCED ROTATIONAL MASS, OFFERS EXCELLENT CLEARANCE.

ATI Super Damper.

The ATI Super Damper is used in all of our high end engine builds. Lower cost dampers are not well suited to operate in the high RPM range especially with engines using the long stoker cranks. These engines do have a more difficult time dampening the harmonics throughout the RPM range. These harmonics in this rpm range can be damaging to the crank, bearings, timing chain, and valve train. If a damper is not up to performing it's job well, problems may result and the result may damage in your engine sooner rather than later. Many street rod engine builders are using very low to mid grade dampers on their higher hp engines. The ATI Super dampers are usually more than double and sometimes triple in price as compared to many dampers on the market, but well worth it considering the fact they can make a huge difference in performance and offer great protection for the engine.*

We did not offer this billet timing pointer in the past. However, we noticed that there was a birds-eye view of the timing pointer from the driver side of the engine, so we decided to use these on all of our engines.

HEAVY DUTY SFI RATED FLEXPLATE MADE IN THE USA INCLUDED.

This SFI flexplate is made in the USA and will resist cracking and warpage to a very high degree. One good telltale in identifying a low quality flexplate is the lack of welding on each side where the plate mates to the ring gear. They usually have a pale grey color to them, as they are not coated, and will rust quickly. Ours are welded on both sides, and are much thicker than an OE plate, and are zinc dichromate coated.

We do offer this engine with a manual flywheel. In most cases we do have both sizes, 153 and 168 tooth, available.

Our CWT 5500 Balancer.

We do our own balancing with our new state of the art CWT 5500 Series balancers . The CWT 5500 is the ultimate for precision balancing. We now have three of these in our machine shop. We consider this machine to be highly advanced compared to the Hines balancer we once used. We balance every rotating assembly we sell within 2 grams or less at no extra charge. A balance sheet is included with your engine.

Three new CWT balance machines under one roof is a rare sight.

Our crew wrapping up for the day. Pardon the mess.

The AFR heads are the best aftermarket cylinder heads in the world. Quality, performance, and reliability are excellent.

Head gaskets are Fel Pro 1014 premium race grade series, and ARP head bolts, and rocker studs.

ARP HEAD BOLTS AND WASHERS.

Scorpion Race series 1.5 OR 1.6 ratio roller rockers with 7/16 ARP rocker studs. We recommend the 1.5 ratio for better low end response and extended valve train life.

THE BEST HIGH PERFORMANCE RACING ROCKER ARMS MANUFACTURED IN THE USA.

We were amazed at the low level of sound produced in the valve train when we did a test run using our first set of Scorpions. We attribute this quiet operation to the close tolerances in the trunnion section. The trunnion barrels are also micro polished.

The rockers have a lifetime warranty. The aluminum body is made from a 7000 series aircraft alloy. Most rockers have a considerable amount of side play in the trunnion section, and may have an excessive amount of needle bearing clearance. The Scorpion does not have much of a loose feel in the trunnion. Many round track and drag racers run these at very high rpm levels and even run them on solid roller setups. With the milder spring pressures of our engines, these rockers should last a lifetime.

All Scorpion Rockers Feature:

Needle Bearing Fulcrum and Roller Tip, Centerless Ground Trunnion, Centerless Ground Pin & Roller, Burr-Free Thru Hole in Trunnion, Large Machined Seat, Thick Walled Adjusting Nut, Pedestals Machined from Solid Steel, Black Oxide Coated Steel Parts, & 100% CNC Machined.

Important notice.

If you have read our warning on engine builders using low grade no-name rods and cranks, a very similar situation exists in the roller rocker market. We do not use or sell off-shore, (no-name) roller rockers, period. They have proven to be faulty in many ways. The center trunnions are not polished, nor is the center of the roller tip true to size or polished. Metal fragments are often left inside the trunnion housing and will cause destruction of the needle bearings. The aluminum alloys used are never aircraft aluminum alloys as are used in all USA made roller rockers. They often mention the alloy as being 6061, and that is a very soft form of aluminum. The 6061 alloy used on these will assure rocker-flex on any higher than stock spring pressures, and this will affect performance. The pins and keepers that hold the parts together are often of poor quality and improperly installed. The front roller will usually scoot along the valve tip, as it can't roll properly due to rough internal surfaces.

We have honestly seen valve tips that were scalloped out due to the front roller dragging across them. This will cause the valves to side-load against the valve guides in the heads and surely cause damage to them if run like this for very long.

We have scrutinized these products in the past and found all of the above problems, and I can tell you there are most likely many more. We would not use them in an engine under any circumstances. You will also see many of these rockers made from stainless on the market. They use a very low grade stainless that actually has a near non-existent amount of nickel in them, but that's not the real problem with them, as stainless steel has no advantage over high grade heat treated steel when it comes to a roller rocker. The lack of hardness of the rocker body is the real problem. The problems with these stainless rockers are the same as mentioned above. These are the roller rockers you see on the market for around $119 and up to $169 for the so called stainless ones. They are pure junk, in our honest opinion. They could possibly be used on a budget back yard stock build up that has a very low spring pressure, with a cam that has very low lift, but then you would be better off with the stock stamped rockers on such a build.

We have heard of many engines using these rockers that came apart and spilled needle bearings into the engine, only to end up in the oil pump. It seems like some engine builders do not care how long the parts in your engine last, or they simply don't know this. I can tell you for sure that using such low grade, "no-name" roller rockers is asking for trouble.

We use Comp Ultra Pro Magnum rockers in all of our BBC engines. The difference in these compared to the low grade no-name rockers on the market is huge. We have on occasion used the Scorpion Race series line or the Comp Gold Arc roller rockers in our engines when the Comp Ultra Pro Magnums are not available.

HOWARDS TIE BAR LIFTERS, HOWARDS CHROMOLY 1pc. .080 WALL PUSHRODS.

We use Howards brand premium pushrods in all of our engines. They are lightweight in design, yet very strong. Made in the USA from 4130 chromoly steel. Regular hardened pushrods will most likely flex in the engine when running above normal RPM ranges, and risk bending under high RPM. These do not have the welded ball on the end. We only use the swedged one pc. design, which is a well proven design far superior to the style many others use in engines. 4130 chromoly steel is also much stronger, and will resist flexing. When a pushrod flexes in the engine, you lose lift. Don't be misled by the term "hardened," as this is nothing more than a stock style low cost push rod. They will flex in the engine or possibly bend permanently.

Our choice of lifters are the Howards brand tie bar lifters. They greatly reduce valve float in the upper rpm range, and have a very quiet operation. These lifters sell for approx. $439 a set. They are a cut above the regular tie bar lifters on the market.

ATM DUAL PUMP MODEL, MECHANICAL SEC. MILLED AIR HORN.

We are offering four cam choices listed below in this engine. Read the specs carefully.

Cam choice # 1

Comp Cams SBC Xtreme Energy Step Nose Hydraulic Roller Camshafts.

253/261 duration

110 lobe sep.

This cam is the most aggressive of the four choices listed. It will make its peak horse power at approx 6300 rpm. The idle is very radical. Power comes in around 3000 rpm.

We recommend a stall converter of around 2800-3200, preferably closer to the high side of this range. Final gearing would need to be at 355 or higher if used in a car weighing more than 3400 lbs. A 373 final gear is most optimal with this cam, providing the car is reasonably light. This cam does make the most horse power but will trade off bottom end throttle response and low speed cruising in the low rpm range.

You would not be able to run an overdrive trans with this cam choice unless the rpm range in overdrive is approximately 2300 rpm. Valve train life is reduced with this cam as compared to the other choices. This would only be a concern for those wanting to drive their vehicles on long trips or with frequent use. This cam choice puts your setup into the Pro-Street league.

Drivability is fair at best with this cam. The exception to this would be those with very light cars, weighing below 3000 lbs. Those with an automatic trans in cars weighing 3300 lbs or more should have a 373 or higher gear if they chose this cam choice.

If your car is in the approximate range of 3900 lb or more, we advise against this cam, regardless of gearing or stall. If you're on the fence with this cam choice and the one below, then you may want to go with this cam and keep the rocker ratio at 1.5, or go with cam choice 2 and go with a 1.6 ratio. That would put you somewhere in the middle of cam choice 1 and 2, at least in respect to valve lift.

Important note,

Official Dyno report on our 427 engine with cam choice #1, AFR heads, a single plane intake, 1.6 rockers.

Cam choice #2

Comp Cams SBC Xtreme Energy Step Nose Hydraulic Roller Camshaft

243/251 duration

110 lobe sep.

Official Dyno report on our 427 engine with cam choice #2 and a single plane intake, 1.6 rockers, and an SQ-850 carburetor.

Cam choice #3

242/248 duration

110 lobe sep.

Comp Cams SBC Xtreme Energy Step Nose Hydraulic Roller Camshafts.

This cam choice (3) is the perfect all around setup for those wanting a very good bottom and mid range response, while still generating decent power at the top. Horsepower rating would drop an additional 10-15 hp below the cam choice 2 when coupled with 1.5 rockers and the dual plane intake. Drivability and street manners would be considered very good with this cam. Heavy cars, upwards of 3800 lbs or more, would do very well with this cam choice. No need for a high rpm stall with this cam, but you would still require a stall in the 2200-2500 rpm range for optimal acceleration.

If your car is in the heavy weight range, and/or geared on the steep side and you want much better streetability, then this is the correct cam choice. You still want to keep the final gear ratio at approx. 320 or higher, but keeping the gear ratio on the tall side is more acceptable with this cam compared to the other choices. If you have an overdrive trans., then this cam, coupled with the dual plane intake, would allow the engine to cruise in overdrive with rpm in the 1850-2000 rpm range. Should you have a Turbo 350 trans, then this cam choice would allow you to run a somewhat taller final gear to allow decent highway driving in the somewhat lower rpm ranges.

You may choose 1.5 or 1.6 rockers with this cam, but we recommend the 1.5 rockers for even better low end response, especially if you plan on running an overdrive transmission. You can also expect a much longer valve train life with this cam compared to the larger cams listed above, especially with the 1.5 ratio rocker choice.

Carb size when using this cam will drop. You'll notice slightly better mileage and better throttle response with this carb versus the larger carbs required when running the larger cam. If your vehicle is very heavy, over 4200 lbs or a full size sport truck, then we recommend our cam choice #4.

Comp Cams SBC Xtreme Energy Step Nose Hydraulic Roller Camshaft

236/242 duration

110 lobe sep.

This cam choice (4) is the perfect all around setup for those wanting a very good bottom and mid range response, while still generating decent power at the top. Horsepower rating would drop an additional 10-15 hp below the cam choice 2 when coupled with 1.5 rockers and the dual plane intake. Drivability and street manners would be considered very good with this cam. Heavy cars, upwards of 3800 lbs or more, would do very well with this cam choice. No need for a high rpm stall with this cam, but you would still require a stall in the 2200-2500 rpm range for optimal acceleration.

If your car is in the heavy weight range, and/or geared on the steep side and you want maximum streetability, then this is the correct cam choice. You still want to keep the final gear ratio at approx. 320 or higher, but keeping the gear ratio on the tall side is more acceptable with this cam compared to the other choices. If you have an overdrive trans., then this cam, coupled with the dual plane intake, would allow the engine to cruise in overdrive with rpm in the 1800-1900 rpm range. Should you have a Turbo 350 trans, then this cam choice would allow you to run a somewhat taller final gear to allow decent highway driving in the somewhat lower rpm ranges. It is also recommended to use the dual plane Edelbrock RPM Airgap intake with this cam for those running AC and/or overdrive transmissions or you may use or Weiand Team G single plane intake. This intake delivers excellent power in the low and mid rpm range. AC and power brakes are not a problem when running this cam with the low rise Weiand intake.

You may choose 1.5 or 1.6 rockers with this cam, but we recommend the 1.5 rockers for even better low end response, especially if you plan on running an overdrive transmission. You can also expect a much longer valve train life with this cam compared to the larger cams listed above, especially with the 1.5 ratio rocker choice.

Carb size when using this cam will drop. You'll notice slightly better mileage and better throttle response with this carb versus the larger carbs required when running the larger cam.

The information above on cam selection is not etched in stone. You could step outside these guidelines towards the more aggressive side, but the driving experience may not be as exciting as if you stayed on the conservative side. The larger cams could possibly cross the finish line sooner in cars that are setup properly compared to the smaller choices, but the smaller cams will have a better feel in a narrower power band without all the drama of the more radical setups above.

We're all hungry for as much horsepower as we can get, but building an engine of a given size to higher horsepower will always require a trade off. The 427 engine offers the best of both worlds when it comes to bottom and top end power, but the bigger cams are more demanding on gearing and stall, sensitive to weight, and suffer on drivability as well as valve train wear and tear.

THE CAMS LISTED WILL COVER MOST NEEDS FOR ANY STREET ROD OR SPORT TRUCK.

We have had a few customers wanting to run our Stage 5.2 427/434 engine in a heavy duty work truck such as a 3/4 ton or 1 ton dually used for trailer towing. None of the four cams listed above would be suitable for this. We do have cams for such applications.

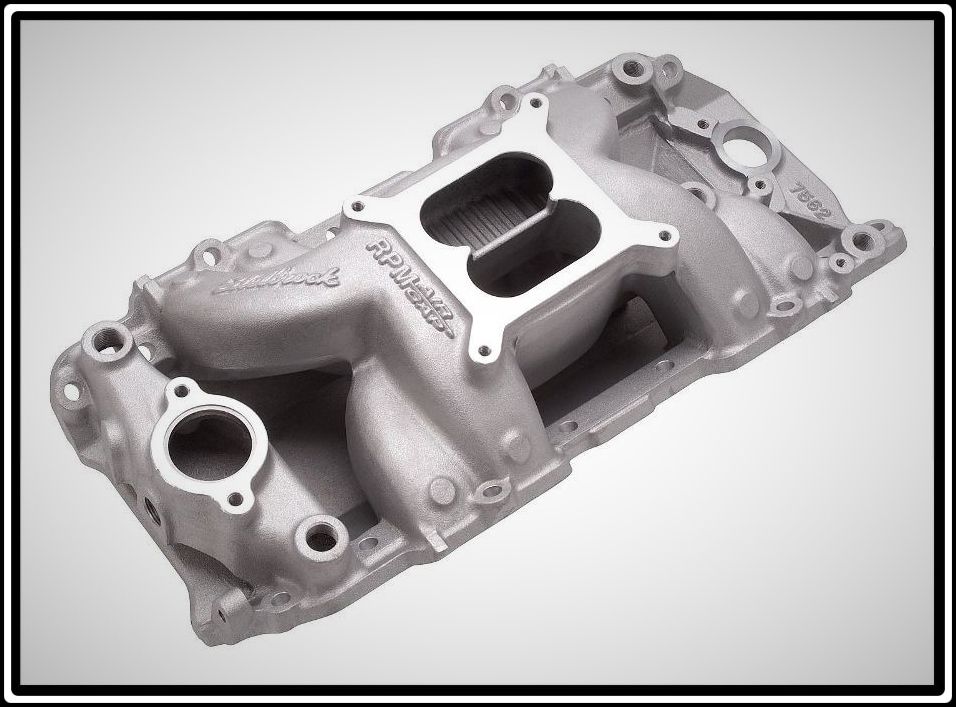

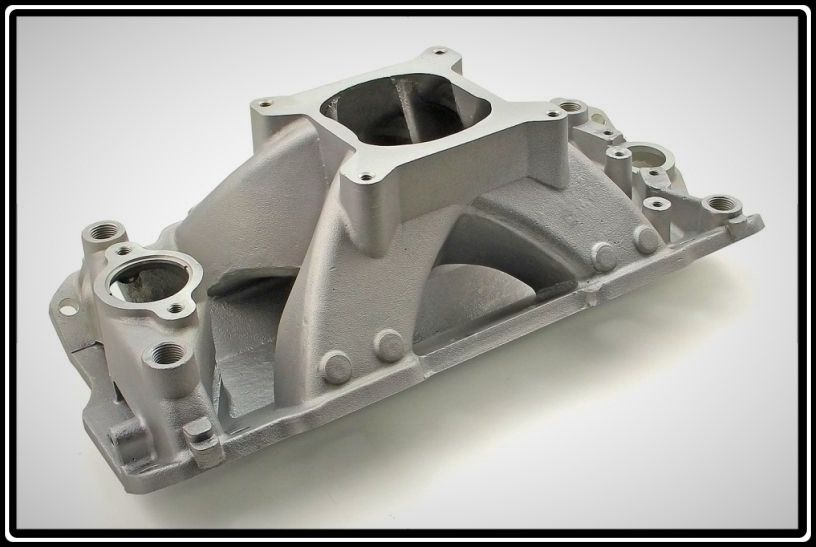

You have a choice of single or dual plane intake. The single plane intake (1st pic below) should only be used on cars that are very lightweight and have good hood clearance.

We now offer the single plane intake in powder coated black finish as a $49.00 upgrade.

Edlebrock RPM Airgap Dual Plane Intake shown below. This is a large runner dual plane intake. They make decent low end power and very good mid range power.

Pictured below is the Weiand 7530WND Single plane intake. If you're going with cam choice # 2 or 3 and require more bottom end power, we strongly recommend this intake. This intake offers decent low end response yet maintains great top end performance when going with cam choices one and two. This intake has excellent hood clearance for those installing this engine in a C3 Corvette with a non-cowl stock hood.

Below is an overhead view of the Weiand Single plane intake.

304 STAINLESS ALLEN HEAD INTAKE BOLTS ARE USED ON ALL OUR ENGINES.

Pictured below are some of our most popular valve covers. They are fabricated aluminum, and very high quality. You may select from any of the valve covers we have listed at no additional cost for your engine.

The satin covers below are by far the most popular.

RETRO STYLE FINNED. OUR SECOND MOST POPULAR CHOICE.

THE RETRO FINNED VALVE COVERS CONTRAST NICELY WITH THE CHROME AND POLISHED ITEMS.

OUR RETRO STYLE TALL FINNED VALVE COVERS HAVE BECOME VERY POPULAR. YOUR CHOICE.

Timing components: SA Gear 8999T billet double roller timing set.

Polished Aluminum Timing Cover.

We use the top of the line SA Gear timing set with a torrington bearing and rolon chain. The difference in quality is dramatic compared to the common low-cost timing set. The upper sprocket is made from billet steel and the lower is induction hardened with nine keyways. These sets are hand matched for selective sizing.

The cost on this high end timing set is approx $97.50, more than double the cost of the low level budget timing set used by many other engine builders. Should you ever want to confirm that this is what is actually in your engine, you can remove the timing cover, and you will see that this timing set is very different in appearance to the run of the mill low cost sets often used by others.

Champ premium oil pan.

If your engine is equipped with the 7 qt. Champ oil pan, it has kickouts that swell outward approx. 3 inches on each side. If you think you will encounter clearance issues with the kickouts, we recommend opting for the stock appearing 5 qt. oil pan. The 5 qt. pan will still be a Champ pan and will have the windage tray and crank scraper. We strongly recommend reducing the amount of oil used in these oil pans by approx. 1/4th of a quart. Doing this may reduce the chance of oil leaks and reduce oil temps. The larger counter weights used on stroker crankshafts are why we recommend reducing the oil capacity in these engines. The higher capacity 7 quart oil pan is an optional upgrade on some of our engines.

To be clear on what we're saying, we would like to see you add right at 6.75 quarts of oil grand total in your engine and oil filter when using the higher capacity oil pan. When using the stock appearing oil pan, we would like to see you add right at 4.75 quarts grand total in your engine and oil filter.

Our engines include a dipstick. It's very important that you re-calibrate the oil level marking on the dipstick. This is due to the fact that the dipstick, oil pan, and block are all made from various manufacturers and we often see great variances. Couple this with the fact that you may be running a reduced amount of oil, and the "full" mark on the dipstick will most likely not indicate correctly. Once you have put a predetermined amount of oil in your engine, and run it for a few minutes, let it sit for awhile on level ground, check the oil, and mark your dipstick with a flat file to re-establish the full mark.

We do not use the knock off oil pan gaskets on the market. Felpro premium oil pan gaskets are used on all of our engines.

Pictured below is a file photo. The actual Felpro gasket used will be the correct model for this application.

We use our premium studded mini nut set on all of our oil pans and valve covers. The nuts have a serrated face and built in washers. This is the ultimate set for securing the oil pan and valve covers to the engine and is far superior to the typical bolts used by most other engine builders. Our standard engine color is black. Custom paint work on engine blocks and oil pans is available as an optional upgrade. The pictures above and below are file photos to display the studded mini nuts. Other items seen in these pictures may not represent your actual engine.

Listed below are more of the items installed on the outside of the engine, which makes it a "Turn Key" engine.

Billet Aluminum Breather set.

If you chose cam choice 1 or 2, then we highly recommend using an exhaust evac. system. The vacuum created by the engine is somewhat insufficient when using these larger cams, heads, carb and intake to operate a pcv system at its best. The exhaust evac system will pull the crankcase gases out of the engine at a very smooth and controlled rate. This allows the rings to seat in much faster and better, and can increase horse power to some degree by reducing crankcase pressure. Another benefit of the evac system is that you're not contaminating the fuel and air mixture with semi-burned byproducts from the engine oil and combustion process.

After the engine is completely broken in, the pcv setup may be sufficient. However, it may not be the best choice. The break-in time may also be slower with the pcv setup.

We also offer a vacuum pump system for the ultimate in crankcase pressure control.

If you do decide to use an exhaust evac system, we have a few more recommendations. The bullet style perforated mufflers, like those made by Magnaflow and many other companies, must be used. In our opinion, they sound the best and, most importantly, they allow the exhaust evac system to work properly. Magnaflow is a popular brand of the true straight through mufflers, and there are several other brands on the market such as Corsa, Borla, and Bullet. The sound level is controlled by the length you choose. The 12-16 inch length sounds the best to us. These mufflers have smooth perforated inner walls. They should not be confused with traditional glass packs with fluted walls, which are very restrictive and have a somewhat sloppy sound.

Traditional chambered mufflers, like Flowmaster, create a back pressure pulse that will interfere with the operation of an exhaust evac. system. Chambered mufflers have the reputation of helping bottom end throttle response, but you will have a decent amount of bottom end power with this engine, especially if you have chosen cam choice 2, 3 or 4. In our experience, the straight through perforated mufflers sound and perform better in every respect, and allow the proper use of an exhaust evac. system. More info. on this subject below.

VERY IMPORTANT NOTE.

If you purchase a starter from us you will have to install it. There is no way for us to properly shim the starter (should it be needed) while the torque converter and transmission are not installed. The flexplate will change position when the transmission is installed and the torque converter is hooked up to the flexplate. Some flexplates have a slight amount of run-out/warpage when the trans. and torque converter are not connected to it. This makes correct starter installation difficult. Only when you have the torque converter mounted to the flexplate can you properly install and adjust the starter.

Suggestion: While the engine is out of the car, still mounted on the engine stand, bolt up your torque converter to the flexplate. This will flatten out the flexplate to a great degree. Then, mount your starter on the engine. This is the only time you will have a birds eye view of the starter gear and ring gear from the back of the engine. You can see if the proper amount of mesh is there.

It's possible that once the transmission is installed and the torque converter is hooked up to the flexplate, the position of the ring gear may move a slight bit more. The transmission shaft centers up to the torque converter, and this causes the flexplate to further change shape slightly. This may alter your initial starter adjustment, and if it does, you may need to do a light adjustment once the transmission is installed.

If your engine is equipped with a manual trans. flywheel, there is no torque converter involved, and installing the starter with the engine on the stand and establishing ring gear clearance is a must. There is no need to bolt on the clutch pressure plate. The thick flywheel is flat and true without anything bolted onto it.

MSD PRO BILLET DISTRIBUTOR. The MSD Pro Billet distributor is a far superior unit compared to any HEI ignition on the market. The failure rate is near non existent. We find the advance curve characteristics also to be more in suitable for street rod engines. We have also noticed that the degree span from initial to total timing is a slightly closer, approx. 18 degrees variance when using the black bushing. This allows the engine to have more initial timing when operating at low speed.

The MSD 85551 Pro Billet distributor is now included in all of our 427 and 434 turn key sbc engines as of purchases made after 7/21/2023 You will require the MSD 6AL box and a coil for this system to operate. The 6AL box and coil are not included with this engine.

The MSD Pro Billet distributor will be installed in the engine.

MSD 50 OHM UNIVERSAL SPARK PLUG WIRE SET AND OUR MSD PRO BILLET DISTRIBUTOR ARE INCLUDED.

Our new 427/434 engine is premium pump gas friendly, with very good street manners. NEVER run regular 87 octane in this engine, premium only. Should you ever hear any sign of pinging or clatter in the engine when accelerating, reduce timing one or two degrees. You can never totally trust the accuracy of timing components.

IMPORTANT NOTE ABOUT DE-TUNING.

For those with very heavy vehicles, such as 4x4 quad cab trucks, 3/4 ton trucks, and crew cab/ex-cab trucks, Suburbans, plus trucks that may do light to medium trailer towing, we strongly recommend the de-tuned version of this engine.

For those wanting to run a supercharger, we recommend our extra deep dish pistons with the 75cc heads regardless of the vehicle.

|

We have dyno tested the original creation of this engine with every cam and intake choice available extensively. We now include the engine test mule run at no additional cost. The engine is thoroughly tested for leaks, vibration, unusual noises, overall engine sound and feel. THIS ENGINE IS BUILT WITH THE BEST AVAILABLE PARTS WITH CONSIDERATION TO KEEPING THE COST OF THIS ENGINE REASONABLE. WE'VE REVIEWED WHAT THE COMPETITION IS OFFERING, AND WE'RE CONVINCED THAT WE ARE OFFERING THE BEST VALUE FOR THE MONEY. We include an engine lift plate and heavy duty engine stand with casters with every engine we build. We offer this engine with selected upgrades. Listed below are some of the most requested ones. Many not only improve performance, but further enhance the reliability and longevity of your engine, along with resale value. Most of these upgrades are low in cost considering the benefits they offer.

We offer premium grade Ram brand SFI Billet Steel flywheels for manual transmission use at an additional cost. See our other listings. This engine includes a flexplate for automatic transmission use at no additional cost.

When purchasing a flywheel for manual transmission use, be sure to know what tooth count you need. There are two sizes available, and it is of the utmost importance to select the flywheel that is correct for this engine. There are several factors that must be addressed when choosing your correct flywheel. The tooth count must be correct. This is very important. There are two sizes available, and it is the bellhousing size on the transmission that determines this. Another important factor is if the engine your purchasing is internally balanced often referred to as neutral balanced or if it is an externally balanced engine, often referred to as externally balanced. Big block and small block engines will also have a different bolt pattern in most cases. To sum it up, there are three important factors to look for when selecting the correct flywheel, tooth count, int. or ext bal. and whether or not you purchasing a big block or small block engine. The Ram brand flywheels we offer are very high quality. See our other listings for a complete line of the Ram brand SFI flywheels.

Race balancing:

This is for those who want the engine to operate virtually vibration free at high rpm. Extends engine life and frees up a few more horse power. This is a somewhat labor intensive procedure and is not required, but the feel of an absolutely vibration free engine at high rpm is desirable by many. The standard balance job that is included with this assembly at no extra charge is certainly sufficient. With a race balance job, all pistons and rods are match weighed to within 2/10's of a gram or less, and the final balance is brought down to around 1 gram plus or minus.

An ultra smooth engine at high rpm has a noticeable feel and sound to it. If you do not opt for this upgrade, the assembly will still be fully balanced. We spend a good hour and a half doing the regular balance work, and it will certainly meet your needs.

Cost of this race balancing upgrade is $125.00 We have this upgrade featured in our other listings. You can see this and other upgrade options in our ebay store under the "UPGRADES" category, or simply do a search with the key word, "Upgrade" in the search bar when shopping in our ebay store. Before you finalize your purchase of this assembly you may add any of these upgrades to your shopping cart. Click here to add upgrades. Wiseco BoostLine Rods and Tool Steel Wrist Pin upgrade . For those wanting ultimate protection in their engine, this upgrade is the answer. The Pro-Pac kit comes with the Wiseco BoostLine rods, tool steel thick wall wrist pins, and ARP 2000 rod bolts. This is an excellent upgrade for those running any type of forced induction, (blowers, NOS, twin turbo, high compression builds). This is also an excellent upgrade for those running naturally aspirated street rod engines. Connecting rod or rod bolts and/or wrist pin failures will usually cause catastrophic damage to the engine. The Pro-Pac kit can handle horse power levels in the 2,000+ range. The 4340 alloy has been through a very special heat treating process. These rods are what we use on all of our extreme high HP applications. As mentioned, this is also an excellent upgrade for medium HP builds that may encounter some hard run time. BBC engines that have been stroked above 4.250 can greatly benefit from this setup. It's well known that engines with long stroke cranks have a greatly increased load on the rods and wrist pins when encountering rpm in the upper ranges. We consider this upgrade very valuable for those that encounter any serious running. The Pro-Pac upgrade includes three actual upgrades: the rods, tool steel wrist pins, and the ARP 2000 rod bolts. Our company founder, Skip White, sums this upgrade up in a few words: "bullet proof." The idea that when you bring your engine rpm up to its limits, and know that the breaking point is often not far away, this upgrade offers a great amount of protection from what could be total engine destruction.

Cost of this upgrade is $1,150 We have this upgrade featured in our other listings. You can see this and other upgrade options in our ebay store under the "UPGRADES" category, or simply do a search with the key word, "Upgrade" in the search bar when shopping in our ebay store. Before you finalize your purchase of this engine, you may add any of these upgrades to your shopping cart. Please go to the "UPGRADES" category of our store to add upgrades.

BoostLine connecting rods are designed from the ground up for high-power forced induction and nitrous applications as well as naturally aspirated engines. A patented 3-pocket design, forged from a special 4340 alloy, maximizes strength while minimizing rotating weight. This revolutionary design dramatically improves the rod's big-end stability under tensile loads and provides a 60% improvement in bending strength and 20% stress reduction in tension compared to H-beam designs. All of these benefits make BoostLine rods ideal for any street rod or racing engine.

In addition to BoostLine's innovative design, comprehensive real-world testing, finite element analysis, and meticulous quality control ensure that all BoostLine rods are fit for 2,000-plus horsepower (8-cylinder applications).

All BoostLine rods include high-quality ARP 2000 bolts. Every rod is inspected and finish-honed in America in addition to being analyzed on a Zeiss CMM as part of the final inspection. A detailed inspection report measuring to .0001 in. is provided with every set of BoostLine rods. Holley Sniper EFI Self-Tuning Fuel Injection System. This has become a very popular upgrade on many of our engines. For those not wanting to deal with the potential quirks of a carburetor, this is the way to go. Drivability becomes greatly improved over a carb. Startup and warm-up are also greatly improved. Tuning stays spot on. These systems make it very easy to tweak the tuning on your engine to better serve your application. Our engine room crew has found the Holley Sniper system to be a very straightforward setup. Some of our customers have requested the Fitech system, and we find them to be an inferior product in many ways to the Holley Sniper system. The customer service offered by Fitech also has been a very poor experience for us. There is no comparison in the way the two systems function, nor in the way they are set up. The Holley system is 100% made in the USA and that is not the case with the Fitech system. The Holley system has a slightly higher cost, but is well worth it, in our very strong opinion. Our company founder, Skip White, stated that he has no problems with running a carb on a street rod engine, but the ability to tune the engine to perfection and the fact that fuel metering is so perfect with the EFI system has changed how he thinks an engine should receive its fuel and air. The difference in drive between the two is vast, to say the least. Cost for this upgrade is calculated by taking the retail difference between the carburetor that comes with this engine and the retail cost of the Holley Sniper EFI System. This is a great value with many benefits, in our opinion. You can see this and other upgrade options in our ebay store under the "UPGRADES" category, or simply do a search with the key word, "Upgrade" in the search bar when shopping in our ebay store. Before you finalize your purchase of this assembly you may add any of these upgrades to your shopping cart. Click here to add upgrades. Dyno Tuning (Carbureted Engines): This is one of the most important upgrade/options we offer. There are many benefits to this service. The engine is first run at fast idle to bring the water and oil temp up to normal operating temperature. It is then run for approx. 20 minutes under a simulated load at around 3k rpm to promote initial ring seating. After this, the engine is shut down to allow us to check the readings on the spark plugs, and for any possible oil leaks. This cool down is considered part of the engine's first heat cycle. We then follow up with multiple low to medium rpm runs to further the break-in process of all the moving parts in the engine. During these multiple runs, we are paying close attention to the EGT (exhaust gas temp) readings, vacuum pump readings, oil temp and pressure, coolant temp, and overall engine sound. At this point, we start the actual dyno tuning process and this focuses around the air to fuel ratio numbers and what timing numbers produce peak power. We usually have to change carb. jetting several times, adjust the idle circuits, and the air-bleeds occasionally have to be changed. We then establish the engine's full horse power and torque numbers at a given rpm limit. Having your engine dyno tuned will allow it to run at its absolute best, and is very important in protecting the engine from potential damage caused by the carburetor running excessively rich or lean. This also establishes the engine's hp output and max rpm. These numbers are very important to know. There is one more value that we consider just as important to what we have mentioned above. An engine that has been dyno tuned has also been validated to be in perfect operating condition. This is something that running the engine on a test mule can't provide. Any problems the engine may have will show up during the dyno tuning process. We have on rare occasion seen a popular combination show hp numbers that were not where they should be. Some of these problems give no indication other than reduced hp numbers. We find and fix such problems. The problem may be something simple and easy to find and in some cases very difficult to pinpoint. We will not send the engine out until it's perfect. If you choose not to purchase the dyno tuning package, we will still do a test mule run, as many engine builders do, and it certainly is better than nothing but pales in comparison to a full dyno tuning. When engines are dyno tuned, the chances of you having a problem are near non-existent. Unforeseen problems may still occur, but they are rare. We have kept the cost on this extensive procedure low to not only make it affordable, but it gives us great peace of mind knowing the engine will be in perfect operating condition when it is received. The cost to do a repair once the engine is installed can be very expensive for both us as the seller and for the customer. When you see the final dyno run of your engine on youtube, consider the fact that approximately five man hours, around $25.00 worth of fuel, oil and filter, and $105K worth of dyno equipment went into making that one minute final test run video. Cost of the full dyno tune option for carbureted engines is $360.00 We have this upgrade featured in our other listings. You can see this and other upgrade options in our ebay store under the "UPGRADES" category, or simply do a search with the key word, "Upgrade" in the search bar when shopping in our ebay store. Before you finalize your purchase of this engine, you may add any of these upgrades to your shopping cart. Click here to add upgrades. Cost of the full dyno tune option for engines with EFI fuel systems will be $100 more. Pictured below is one of our actual Super Flow dyno's. This is a 2016 model and highly advanced compared to the much older models many shops have. We have two of these in use at our shop.

The Super Flow is the best dyno in the industry.

IMPORTANT NOTE ABOUT DE-TUNING. For those with very heavy vehicles, such as 4x4 quad cab trucks, 3/4 ton trucks, and crew cab/ex-cab trucks, Suburbans, plus trucks that may do light to medium trailer towing, we recommend the de-tuned version of this engine. For those wanting to run a supercharger, we recommend our extra deep dish pistons with the 75cc heads regardless of the vehicle. Our machinists each have many years of experience in building racing engines. This very critical work is done to exacting specs and with great care. Many vendors do not have machinists with the experience or the proper equipment that we are fortunate to have. We have built engines that cost upwards of $50,000. All of our engine builders have been in the engine machining and engine building line of work for their entire working lives. Their ages range from 40 to 67. We have a total of seven machinists/engine builders.

|

|||||||||||||||||||||||||||||||||

Attention Valued Customers!

When it comes to highly technical questions, our sales team at Skip White Performance might not always have the detailed answers you're looking for, especially on topics like installation procedures or tuning.

For those with detailed or specific questions, we strongly recommend checking out automotive forums and communities where these products are frequently discussed. These forums are a treasure trove of information and can provide the expert advice you need. Additionally, YouTube has countless tutorials and guides that walk you through the installation process and other technical details.

Please note: While we're here to provide top-notch products, we cannot be held responsible for any damage resulting from the use or installation of this product. Make sure to do your research and proceed with caution!

Thank you for choosing Skip White Performance!

Disclaimer

Skip White Performance is not liable for any collateral damage or incidental issues arising from the use or misuse of our products. High-performance parts are intended for experienced professionals and enthusiasts. Use at your own risk.Product Information

| UPC | 333915779219 |

|---|---|

| Product Type | Shipped Product |

| Price (excl. tax) | $14,495.00 |

| Price (incl. tax) | $14,495.00 |

| Tax | $0.00 |

| Availability | Available |

| Shipping Cost | 435.0 |

| Number of reviews | 0 |

Customer Reviews

This product does not have any reviews yet.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)