BBC CHEVY 572 ROTATING ASSEMBLY K1 4340 WISECO +14.5cc DOME 4.560 BORE X 4.375 STROKE

$2,850.00

Available

FULLY BALANCED/FULLY FORGED BBC CHEVY

572

ROTATING

ASSEMBLY WITH WISECO FORGED

+14.5cc

DOME PISTONS.

4.560

BORE X

4.375

STROKE. K1

4340

INT.

BALANCED CRANK

SHAFT.

SCAT

6.385"

H-BEAM RODS.

For use in a standard deck height, (9.800) aftermarket block

The picture above is a file photo. See the detailed info below for the actual pictures and items included in this assembly.

Fully balanced in house.

READ THIS LISTING COMPLETELY BEFORE YOU BUY ELSEWHERE!

This assembly comes with a K1 crankshaft and 4340 Scat rods, Total Seal high performance rings, King bearings, and a heavy duty 168 or 153 tooth flexplate and a Pro-Race brand damper. See details for all the actual specs of this assembly. In the lower section of this ad is information on the various upgrades we offer in our other listings.

Crankshaft Specs.

- Crankshaft: K1 Technologies, Internally Balanced.

- Crankshaft Stroke: 4.375"

- Crankshaft Material : 4340 Fully Forged

- Journal Diameter: STD BBC

- Rear Main Seal: 2 pc RMS

- Rods: Genuine Scat

- Rod Type: Genuine Scat H-beam.

- Rod Length: 6.385"

- Rod Material: Forged 4340 Alloy.

- Rod Bolt/Cap Screw: ARP 8740 Cap Screws.

- Pistons: Wiseco Fully Forged. High Performance for street/strip use.

- Piston Size: 4.560" (Actual cid is 572)

- Dome Volume: +14.5 cc Dome Top

- Compression Height: 1.218

- Piston Material: Forged 2618 Aircraft Alloy

- Piston Rings: Total Seal High Performance, Standard Tension.

- Ring Size and Fit: 1/16 1/16 3/16 File Fit.

- Ring Material: Ductile Iron/Cast/Stainless/Moly

- Main Bearings: King MB557HP High Performance

- Rod Bearings: King CR807HP High Performance

- Balance: In House on CWT balancer.

- Damper: ATI Super Damper SFI internally balanced 7.074"

- Flexplate: Heavy Duty 168 tooth or 153 tooth. Manual Trans. flywheels available.

Compression Ratio Chart

The calculations below assume your pistons are at zero deck. Let's say your compression calculates out to be 10.50:1 for example based on having the pistons at zero deck (flush with the deck), but your pistons were going to be .005 in the hole, then the comp. ratio would only drop to approx. 10.36, and if left .010 in the hole, then it would drop to approx. 10.22 We do recommend having your block decked to allow the piston to set anywhere from flush (zero) to .005 in the hole for optimal performance. We used a 4.630 head gasket diameter, and a .040 head gasket thickness in our calculations to come up with our comp. ratio values.

|

Part Number |

Cylinder Head Volume |

||

|

117cc |

119cc |

121cc |

|

|

572 Assembly |

Static Compression Ratio |

||

|

4.560 Bore |

11.31 |

11.13 |

10.96

|

Listed below is a complete breakdown of all the parts that are included in this assembly.

Our custom made Wiseco pistons are rated very high in the street/strip performance industry. Wiseco normally offer several grades of pistons, starting with the lower grade Pro-Tru Street version made with 4032 forged alloy. The next level up would be the professional series that are much more expensive and made from 2618 aircraft alloy and have fully machined crowns rather than the as cast crowns that are on the Pro-Tru series. Our Wiseco pistons are custom made for us, and have both of these premium features, 2618 Alloy, and fully machined crowns. All premium grade forged pistons on the market have these two unique features and usually cost around $800-$1100 per set.

We have built approximately 8000 engines using the Wiseco pistons over the past 10 years. The engines have been for street rod and strip use. We have seen no problems, nor have there been any complaints. They are an excellent product in every respect.

Important note

Many customers have asked us what size they should bore their block at to allow for a proper piston to wall clearance. The required clearance is built into the piston already. For example if these pistons show a given size such as 4.030 then that is exactly what you will bore the block to. The actual size of the pistons when measured at the skirt, 1/2 inch above the tang will show to be approx. 4.026. The needed clearance is built in. Should you be using these pistons in a marine app. where the boat receives it's water from the lake, then an additional 1.5-2.0 thous. would be added to your final bore size, and some forced induction apps may also require a slight increase in bore size.

These pistons are totally suitable for use with mid level nitrous or blower setups. Extreme level builds that are making hp numbers in the 1000 hp range will require a set of custom made extreme duty pistons.

Our Wiseco Forged pistons are custom designed with an increase in compression height. This has many advantages. Here are a few facts about compression height and deck height.

Our custom made Wiseco pistons have a compression height that is .010 taller than nearly all catalog pistons on the market. We find this to be a very valuable feature. Since our pistons sit at a taller than normal compression height, you will only have to remove approx. .005-.010 off the deck surface of a virgin block to achieve a zero deck. This also allows for future deck re-surfacing and still not ending too far below stock deck height.

Leaving the deck on your block thick makes for a stronger block that resists flexing and also runs cooler, as the deck thickness has a lot to do with the dissipation of heat. Blocks with decks cut down to any great amount are also prone to cracking. This is why our pistons are designed to sit flush, (zero deck) at .010 below stock deck height.

Since nearly all bbc catalog pistons on the market sit .020 below the surface of a virgin block, the only way to achieve a zero deck using such pistons would be to cut .020 off the deck surface. This compromises the integrity of the block, in our opinion. Should you decide to leave the block deck higher up, using such pistons creates a new issue of having a very poor quench/squish zone. The only way you could really take advantage of a catalog piston is by having a block that needs to or has already been butchered down to 9.780 deck height. Having the piston sitting flush with the deck is very desirable, regardless of the fact that your overall compression ratio is slightly higher than if it were sitting below the deck.

We have found that 95% of our customers are using a virgin block or a block that is close to stock deck height. This is why we have designed our pistons to have a taller compression height. On very rare occasions, you may end up with a block that has the piston out of the hole by a few thousandths and this not a problem at all. Most head gaskets are approx. .040 thick, and should you end up with a quench zone of .035, then that is ok. If the quench zone ends up below .035, then there are plenty of .050 thick head gaskets on the market. One more benefit to this is that most machine shops charge much more to deck a block down from stock deck height to 9.780 than they would to do a light cleanup, and that's all that's needed when using our Wiseco pistons.

Another good feature about our pistons having a taller compression height is that the ring land above the top ring is much stronger by being .010 thicker. When pistons encounter the effects of detonation, it is not uncommon to see pistons with the ring land above the top ring broken off. The thicker ring land also makes a better heat sink.

You may have noticed that our Wiseco custom made forged pistons are referred to as Racing Pistons on the package. This does not mean that the pistons are for racing only. This is a generic term, referring to their ability to be used in high performance applications as well as for street rod use. These pistons are perfectly designed for use on the street, as well as for medium to upper level drag racing.

Our custom made Wiseco forged pistons are made from 2618 aircraft alloy. We find this alloy to be much more suitable for high performance engines than the common 4032 forged alloy. You will usually see the higher end pistons on the market using 2618 aircraft alloy.

Why go with 2618 forged pistons? If you encounter certain tuning issues, detonation is highly probable, and it's effects can cause severe damage to your engine. The 2618 forged piston is able to withstand the damaging effects from detonation to a higher degree than the lower cost 4032 forged pistons, especially non-forged hypereutectic pistons such as Speed Pro or Keith Black, and many others.

Our Wiseco forged pistons will clear most any valve size on the market with ease even with the use of large lift cams.

We have built approximately 3500 engines using the Wiseco pistons. The engines have been for street rod and strip use. We have seen no problems, nor has there been any complaints. They are an excellent product in every respect.

These pistons are also suitable for use with nitrous or blower setups. For the slight increase in cost, this is the best value on the market.

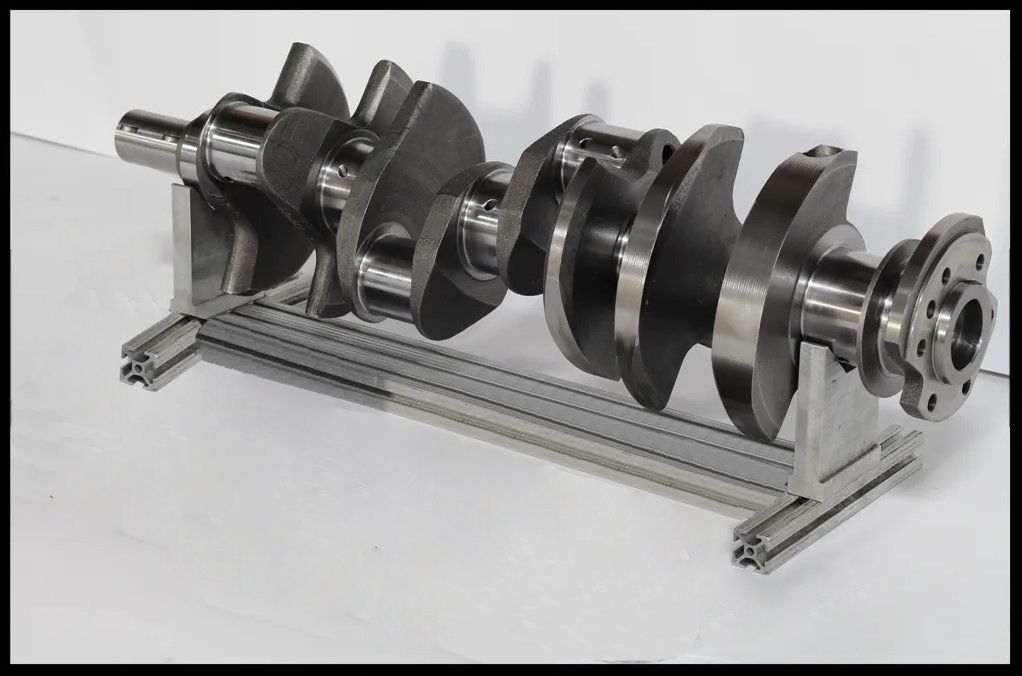

The K1 Technologies crankshaft with 8 counterweights, 4340 Forged Crankshaft.

The picture below is a file photo. Actual appearance will be different.

K1 Technologies crankshafts are made from 4340 forged steel, core hardened and nitride hardened for optimum strength, increased fatigue life and minimized distortion. To help ensure consistent quality each crankshaft is magnetic particle tested to ensure it is free of flaws and journal tolerances are held to +/- .0001” to ensure consistent bearing clearances. We also offer this assembly with the Manley Pro-Series crank. See our upgrades in the lower section of this ad.

We recommend that you check the thrust clearance on the crank before assembling the engine. This is recommended on any crankshaft, regardless of brand or cost. Also be sure to check your main and rod journal size.

Our choice of rods are the Genuine Scat brand heavy duty 6.385 H-beam rods with ARP cap screws.

Genuine ARP 8740 cap screws.

The Scat rods do have genuine ARP 8740 Series 12 point cap screws. Some cams may require slight clearancing of the rods. Be sure to do a roll over test after installing each rod.

We have noticed some sellers using generic rods and crankshafts in their rotating assemblies. These non-branded (no-name) rods and cranks are often poor quality in many ways. You will notice many sellers fail to mention the actual brand of these products. Upon further investigation, you will find such parts not to be a branded name product. They may label these parts with a name, but one that is totally unrecognizable in the industry. Our experience in years past with such rods and cranks has been disappointing, to say the least. Failures of such critical parts in your engine may result in catastrophic damage. Machine shops are sometimes able to correct some of the problems with these low quality rods and cranks, but at great expense to the customer. As for the questionable alloy these items may be produced from and the potentially incorrect heat treating methods used, little can be done to verify this and nothing can be done to correct it. As you may have noticed, this is why we specify the name brand and series of every part used in our assemblies.

Many of the inferior "no-name" rods on the market will also have "no-name" rod bolts in them. We have seen these bolts before, and they are very low quality. They don't have ARP's rolled thread design, and they don't torque down with the same characteristics as a genuine ARP bolt. It's not just a matter of having a different brand bolt in the rods; these bolts are low quality in many ways. They have been known to fail in engines to a much greater degree than a high quality rod bolt, and this failure usually causes catastrophic damage in the engine. Beware of rods that don't mention the rod bolt brand. As far as we're concerned, ARP bolts are the only brand we would ever use or accept in a set of rods.

Before the engine is assembled, we strongly suggest checking the rods on a Sunnen machine for sizing on both ends. We recommend this with any rod regardless of cost or brand. It is not uncommon to find some of the rods requiring a slight bump through the hone for perfection in sizing and roundness. We also offer this kit with a proofed set of rods. This is an excellent choice for those wanting to build the engine on their own.

Total Seal High Performance Rings.

KING MAIN AND ROD BEARINGS INCLUDED.

INTERNALLY BALANCED, SFI rated, 7.074 " DIAMETER, REDUCED ROTATIONAL MASS, OFFERS EXCELLENT CLEARANCE.

HEAVY DUTY FLEXPLATE INCLUDED.

HEAVY DUTY FLEXPLATE. This flexplate will resist cracking. One good telltale in identifying a low quality flexplate is the lack of welding on each side where the plate mates to the ring gear. They usually have a pale grey color to them, as they are not coated, and will rust quickly. Ours are welded on both sides, and are much thicker than an OE plate, and are either zinc dichromate or black powder coated. We would never use the thinner OE style plate on an assembly like this.

We do offer this assembly with a manual flywheel. See our other listings. In most cases we do have both sizes, 153 and 168 tooth, available.

WARNING: the flexplate and crank have a dowel pin hole. You must align the flexplate and crank dowel pin holes, but do not use a dowel pin. The flexplate was aligned to the crank when we balanced the assembly, and must be installed the same way.

Our CWT 5500 Balancer.

We do our own balancing with our new state of the art CWT 5500 Series balancers . The CWT 5500 is the ultimate for precision balancing. We now have three of these in our machine shop. We consider this machine to be highly advanced compared to the Hines balancer we once used. We balance every rotating assembly we sell within 2 grams or less at no extra charge. A balance sheet is included with your assembly.

Three CWT balance machines under one roof is a rare sight.

Our crew wrapping up for the day. Pardon the mess.

We offer this engine with selected upgrades and options. Listed below are some of the most requested ones. Many not only improve performance, but further enhance the reliability and longevity of your engine, along with resale value.

Upgrade to the New Manley 8 counterweight Pro-Series 4340 crankshaft #190320

The picture below is a generic file photo

Some of the benefits of the new Manley Pro-Series crankshaft. This upgrade is offered at a price of $285.00

Manley Pro Series crankshafts can make your engine bulletproof. They feature forged 4340 construction and undergo a multi-step heat-treatment process and are then nitrided for added strength. The crankshafts are stress-relieved, shot-peened, and magnafluxed. Manley Pro Series crankshafts have micro-polished large .125 in. radius journals, gun-drilled mains, and lightened rod journals for weight reduction. The counterweights are fully profiled and they are designed for internal balancing. These crankshafts will include a spec. sheet that validates journal sizes and checks for taper on each journal as well as finish quality.

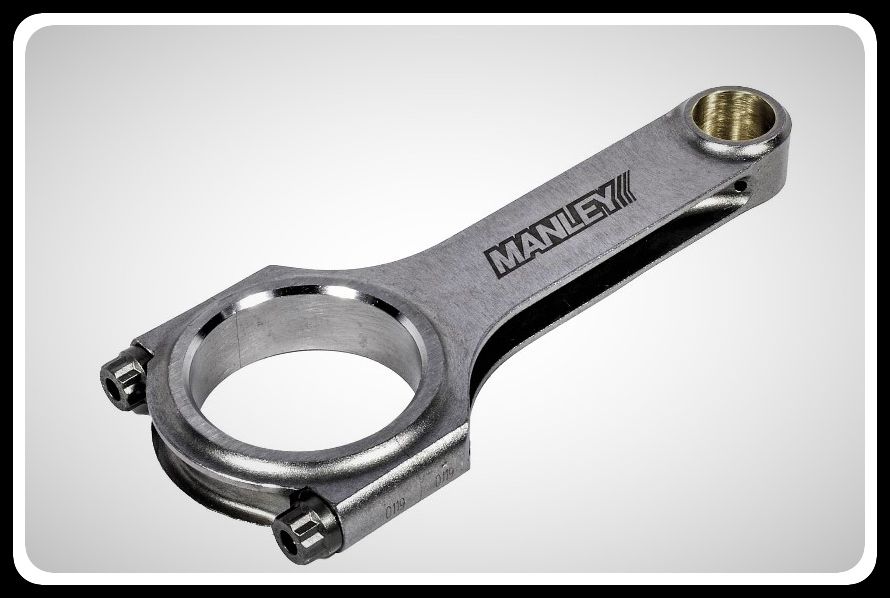

Upgrade to the Manley 6.700 H-beam rods with ARP 2000 cap screws.

The Manley H-beam rods are very high rated in the racing industry. They easily outrank most of the other common brands on the market. This rod upgrade is offered at a price of $285.00

All of our Manley rods come with Genuine ARP 2000 cap screws.

SFI Certified Flexplate: Cost of this upgrade is $24.50, This is a very low cost upgrade and may be required when racing your car at certain tracks. The flexplate that comes with this assembly is a heavy duty plate, but the SFI certified plate is one step up in quality and safety. This SFI plate is made in North America. We noticed these have much less run-out and warpage than we see with many other plates on the market. Plates with too much run-out and warpage can cause a host of problems for your transmission and starter, and affect balancing. The low cost to upgrade to this is well worth, it in our opinion.

On occasion we are unable to obtain the Pioneer brand SFI flexplate and will substitute it for the Scat SFI brand plate pictured below. The quality is equal in every aspect.

Crank polishing: Cost of this upgrade is $39.50, Extends bearing life, reduces oil temp, frees up a slight amount of average horsepower. This is a very low cost upgrade, and in the world of mass production, most cranks do not come with a true polished finish. This is why most machine shops have a machine to do this. The difference is dramatic between a crank right out of the box and one that we have polished. Bearing companies claim that cranks that have better finishes on the journals will survive the break-in better, and have much longer bearing life. We do a two-step process and bring the RA numbers down in the single digit range. We have the most advanced crank polishing machine on the market.

Clevite Bearings: Cost of this upgrade is $60.00, We find the Clevite bearings to be a somewhat better product overall. Clevite is what we now use in all of our engines. This is not to say that King bearings are faulty in any way, but under certain conditions, we have seen fewer problems develop with Clevite bearings during break-in. We have sold King bearings for many years and do not hear of problems from our customers, but our experience on the dyno has shown the Clevite bearings have a better surface appearance upon tear-down after many dyno passes.

Rod sizing: Cost of this upgrade is $50.00, Sizing the big end and wrist pin bushing on the Sunnen machine saves a trip to the machine shop. All rods, regardless of brand, should be checked for sizing on a Sunnen machine, and corrected if needed. You will seldom see a complete set of rods that have perfect sizing on both ends right out of the box.

Race balancing: Cost of this upgrade is $125.00, This is for those who want the engine to operate virtually vibration free at high rpm. Extends engine life and frees up a few more horse power. This is a somewhat labor intensive procedure and is not required, but the feel of an absolutely vibration free engine at high rpm is desirable by many. The standard balance job that is included with this assembly at no extra charge is certainly sufficient. With a race balance job, all pistons and rods are match weighed to within 2/10's of a gram or less, and the final balance is brought down to around 1 gram plus or minus. An ultra smooth engine at high rpm has a noticeable feel and sound to it. If you do not opt for this upgrade, the assembly will still be fully balanced. We spend a good hour and a half doing the regular balance work, and it will certainly meet your needs.

ARP-2000 rod bolts: Cost of this upgrade is $89.50, This is one upgrade that we find to be very valuable. The rod bolts are most likely to fail under hard use, more so than the rod itself. When a rod bolt fails during high RPM, total engine destruction is usually the result. The ARP-2000 rod bolts are a very good upgrade, in our opinion. We actually have few, if any, problems with the regular ARP-8740 bolts, but those who run hard always upgrade to the ARP-2000 rod bolts. The ARP-2000 rod bolts also torque at a higher number, and this increased clamping force is also a factor in keeping the big end of the rod stable and true to size. The ARP-2000 bolts are installed in the rods and this upgrade is only available with the Competition rod upgrade.

The upgrades above are all available in our other listings. Some of these are often requested by those building an engine without a machine shop. We find most of these upgrades very valuable for those wanting to take longevity and durability to the next level. They are all bottom end related, and that's an area worth investing a few more dollars into, in our opinion, especially if you're planning on running long and/or hard. These upgrades are also valuable for your build history on your engine, and would certainly increase the resale value of your engine, should you ever sell it.

Rust warning.

If you are going to store your rotating assembly or short block kit for any length of time, it is very important that you protect these parts by spraying a light coat of rust preventive substance on all bare metal parts. This is especially important for those storing these parts in a high moisture or humid environment. Very light surface rust is easily removable and will cause no harm, but heavy rust can damage these parts and be very costly to fix.

Our thoughts on what the competition has to offer.

Many rotating assemblies we see on the market are not using the most suitable parts. We hope you can value the fact that we have put together an above average assembly. The failure rate with the parts used in our assembly is near non-existent. It was through trial and error in years past that taught us where to draw the line with low cost parts. We are out-priced by many others selling assemblies that include parts that have high failure rates. Many of these parts also pose a great problem with assembly due to the fact they require additional machining and can end up costing you a great deal more money and time. If you're going to have a machine shop build your engine, we strongly advise you get an opinion from them on the parts you're going to be bringing to them. Rest assured they will find no problem with the quality of our parts. We have also seen sellers offering parts that are not compatible with what most people are building. We have seen several sellers offering no-name brand rods with an assembly. These type of rods also have no-name bolts in them. It is our strong advise to avoid assemblies with these grade of rods. The low grade dampers and flexplates are also another problem. Another area of concern would be balancing. Not sure how much attention these sellers are giving the assembly in this area. We spend up to two hours balancing an assembly, and using the very best up to date balancing equipment on the market. If the assembly is not balanced properly, it will hammer the bearings out of the engine, not to mention there is nothing worse than an engine that lacks a smooth feel and sound when under load.

A note from Skip White, company president.

Many people have asked how is it that we can sell this assembly for such a low price. To answer this; we buy our products at master WD (warehouse distributor) level for all of the items in this assembly, and we are selling direct to the public. We are a volume sales based company. Our profit is based on sheer volume, with a very low markup. It is this large volume purchasing that allows us to buy products at a much lower price and we simply pass these savings on to our customers. This is our main competitive edge.

Skip White

|

|

|

Attention Valued Customers!

When it comes to highly technical questions, our sales team at Skip White Performance might not always have the detailed answers you're looking for, especially on topics like installation procedures or tuning.

For those with detailed or specific questions, we strongly recommend checking out automotive forums and communities where these products are frequently discussed. These forums are a treasure trove of information and can provide the expert advice you need. Additionally, YouTube has countless tutorials and guides that walk you through the installation process and other technical details.

Please note: While we're here to provide top-notch products, we cannot be held responsible for any damage resulting from the use or installation of this product. Make sure to do your research and proceed with caution!

Thank you for choosing Skip White Performance!

Disclaimer

Skip White Performance is not liable for any collateral damage or incidental issues arising from the use or misuse of our products. High-performance parts are intended for experienced professionals and enthusiasts. Use at your own risk.Product Information

| UPC | 353414765099 |

|---|---|

| Product Type | Shipped Product |

| Price (excl. tax) | $2,850.00 |

| Price (incl. tax) | $2,850.00 |

| Tax | $0.00 |

| Availability | Available |

| Shipping Cost | 168.5 |

| Number of reviews | 0 |

Customer Reviews

This product does not have any reviews yet.

.jpg?width=1920&height=1080&fit=bounds)